Auto repair industry experts Cecil Bullard and Kent Bullard delivered a much-needed session at the Amplify 2023 virtual conference. The father-son duo tackled a daunting problem for many auto repair shops: KPI tracking.

Cecil is the respective CEO and Kent is the respective COO at The Institute of Automotive Excellence. The Institute has been coaching shop owners and helping them improve business workflows for over a decade. Their mission is to build better businesses, better lives, and a better industry.

As part of the same mission, they conducted an auto repair KPIs training at Amplify 2023. Let’s recap.

» Want to grow your auto repair business? Click here to schedule a demo.

What are KPIs?

Cecil defined KPIs as, “key process indicators that create your profit.”

KPI tracking is super important. Without regularly looking at your business numbers, you’re unlikely to see your shop’s trajectory and plan for growth.

As a shop owner, you need to track five key metrics:

- Sales

- Parts margin

- Labor margin

- Parts costs

- Sales costs

Tracking core metrics

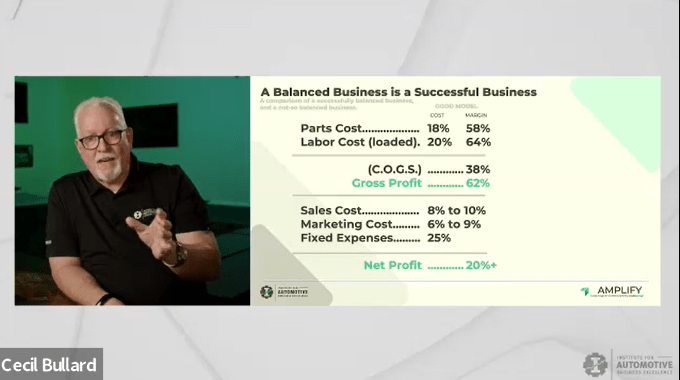

Cecil wanted us to start with a balanced business.

“You start with a balanced business. If we balance our business correctly, we can understand the KPIs to make the profit that we want.”

In order to do this, you need to look at the cost of things compared to the income you bring in. Remember: You have a lot of control over your business and you can control your percentages. Let’s see how that’s done.

Setting the right cost goals

If you don’t do this right, you could end up with negative profit. Our goal should be to hit 20% and over in terms of net profit. We’ll do this by setting the right profit margin and cost goals.

Costs usually include parts, labor, fixed expenses and so on.

Parts include the replacements you utilize. Labor costs, when they are “loaded”, include worker’s compensation, insurance, education, holidays, PTO, and everything that goes into paying a technician.

So, how do we calculate what percentage of our sales should make up our costs? Heads up, a bunch of math coming up. But it’ll be vital in helping you set the right KPI goals.

Let’s get started.

- In a good model, your sales breakdown is 45% parts and 55% labor.

- Also in a good model, you can get your parts margin as high as 58% and your labor margin as high as 62%. While these might seem high, several of Cecil’s clients have met them.

How this system works: You take your target margin and use it to calculate the cost percentages you need to hit. It’s a bit of backtracking to optimize the costs.

So how do we do that?

- Let’s assume your sales are $100K. Then, $45K comes from part sales and $55K comes from labor.

- For a 58% parts margin, we’ll have to hit 18% parts cost.

- This means our cost of goods should be roughly 18K. That’s 18% of total sales if our sales are 100K.

- If we do the same calculation for our labor costs with a set goal of 62% labor margin, we’ll arrive at 20% labor costs.

These are the KPI goals we need for our costs.

If we’re able to meet these KPIs, here’s the net profit you can expect:

- With these cost percentages, our Cost of Goods Sold (COGS) becomes:

18 + 20 = 38%

- That means our Gross Profit comes out to be:

100 – 38 = 62%

- Parts and labor aren’t your only costs. There are other expenses to factor in.

- Fixed expenses include payrolls, perks of the business owner, and things that are always cashed out.

- If we factor in sales costs (roughly 8 to 10%), marketing costs (roughly 6 to 9%), and fixed expenses (roughly 25%), these add up to about 42% of sales.

- Then, with these additional costs, our total COGS comes out to be:

COGS = Parts + Labor + additional costs

18 + 20 + 42 = 80%

- Then, the net profit comes out to be:

100 – COGS = Net Profit

100 – 80 = 20%

These are the healthy benchmarks to aim for. To summarize, the recommended cost benchmarks are:

- Parts costs = 18%

- Labor costs = 20%

- Sales costs = 8 to 10%

- Marketing costs = 6 to 9%

- Fixed expenses = 25%

- Parts margin = 58%

- Labor margin = 62%

With these numbers, you’ll arrive at a net profit of 20%+.

Key tips to hit these numbers

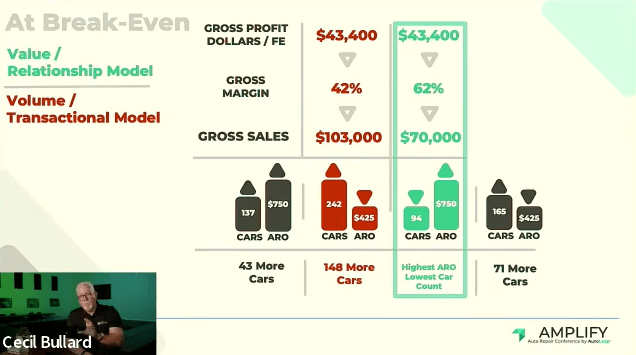

The right strategy to maximize net profit is keeping costs down and profit margins up.

Word of caution: Low profit margins will require that you make more sales for the same profit as a company with higher profit margins. You’ll also need more cars and more repair orders to get to the finish line. Ultimately, that will take your labor costs up as you’ll need more work, leading to a system that makes it even harder to break even.

Here are Cecil’s tips for maintaining the right margins:

- Keep your margins high on parts so that your parts cost is less.

- An eight-hour shift doesn’t mean you get a full eight hours from a tech. Help boost productivity to get more labor for the same time. This brings your labor costs down.

- Allot time for tasks so techs stick to the designated time.

- Choose the value/relationship model over the volume/transactional model. Focus on offering more value at a higher price and building key relationships. This will help raise your Average Order Value and boost sales even with lower car count.

- Don’t compare your costs with competitors. Stick to the service costs that make sense to you.

- Instead, communicate the value to customers for a higher price. Do you have a better warranty? Is your product manufacturer better?

- Focus on providing convenience. Offer impeccable inspections, timely delivery, and great customer service.

- Track effective labor rate instead of labor rate.

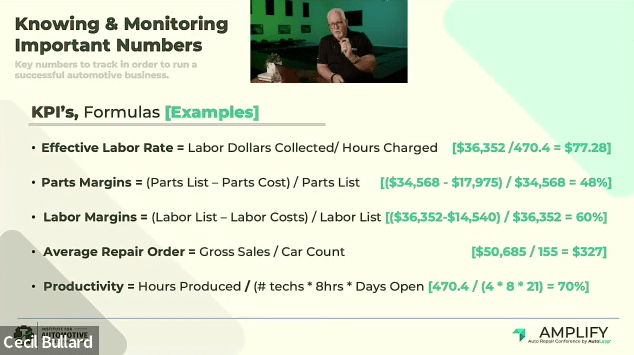

Key formulas

Cecil also shared his list of formulas for KPI calculations. We’ve already used a few of these in the recap. Here’s a quick list:

- Effective labor rate = Labor dollars collected/Hours charged

- Parts margin = (Parts List – Parts costs)/Parts list)

- Labor margin = (Labor List – Labor costs)/Labor list)

- Average Repair Order = Gross Sales/Car Count

- Productivity = Hours Produced/(# of techs x 8 hours x Days Open)

More metrics for business health

Looking at part margins and costs will only offer a high-level insight into your business health. For greater granularity, track the following metrics.

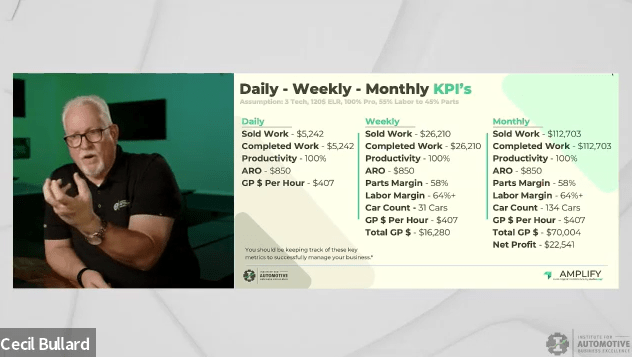

For daily tracking, monitor:

- Sold work

- Completed work

- Productivity percentage

- Average repair order

- GP $ per hour

On top of this, stack the following for weekly tracking:

- Parts Margin

- Labor margin

- Car count

- Total GP $

On a month-to-month basis, track the Net Profit in addition to the rest of the metrics.

» Looking to transform your shop? Discover how AutoLeap can help.

Final thoughts

At the start of this all, number tracking seems overwhelming. But it’s what helps keep us on track and ahead of the curve.

Track the right KPIs, diligently monitor them, and don’t compromise on your shop goals. Good luck.

Frequently Asked Questions (FAQs)

Most vehicles from 1996 models to now are compatible with the OBD-2 scanner. However, if the vehicle is older than 1996, then you might need an OBD-1 scanner.

Using an OBD-2 scanner will not hurt your vehicle’s warranty. But if any issues or faults occur because you worked on the car or tuned it, it will void your vehicle’s warranty.

OBD-2 scanners with advanced features and functionalities support different makes and models. But you should always check if a certain vehicle is compatible with your scanner.

OBD-1 was a scanner used in earlier years. It connects to the console of a car. The OBD-2 is an advanced version of OBD-1 that most modern shops use. It offers better signaling protocols and messaging. It also provides more accurate results.

Software updates are available quarterly, after six months, or annually. Updates may become available online. Advanced updates might come about after a year. Your tool provider can guide you on specific update releases.

Demo

Demo