One of the most important investments your shop will make is a car lift. And when it comes to choosing between the two main types of car lifts, symmetrical and asymmetrical, there are some key points you need to consider.

In this blog, we explore the features, benefits and disadvantages of asymmetrical vs symmetrical lifts. Let’s get started!

Schedule a free demo today!

Boost your shop sales

Simplify shop management

Empower your technicians

The modern appeal of two-post car lifts

Two-post car lifts are a great place to start your research. These lifts are found in almost every auto repair facility, especially drive-in shops. They operate with four adjustable arms to lift vehicles for your techs to work on.

The versatility of two-post usage is a key factor in this lift’s appeal. Technicians can easily execute maintenance required underneath the vehicles, including engine and gearbox work, thanks to its advanced lifting capacity.

For a shop with a lower ceiling, two-post lifts are among the best options. Light trucks, vans, and standard vehicle sizes work with two-post lifts, which can lift up to 20,000 pounds in total (depending on the lift).

Finally, during installation, two-post lifts attach to the ground. This effect helps to increase durability for long-term use if you intend to keep your lift stationary.

Types of two-post lifts

There are three main types of two-post car lifts:

- Symmetrical car lifts

- Asymmetrical car lifts

- Super symmetrical car lifts

Super symmetrical car lifts are a contemporary new design that warrant mention. But when it comes to the two main contenders for your general repair shop, symmetrical and asymmetrical lifts stand out above the rest.

So what is the difference between these two car lifts? And which option should you choose for your auto repair business? Let’s explore these questions in depth.

Symmetrical vs asymmetrical car lifts - what’s the difference?

First, some background information on the lift dynamic. A lift’s arm configuration is referred to as symmetric or asymmetric.

To put it simply, symmetrical lifts have arms at the front and back that are the same length and design. Asymmetrical lifts have arms at the front and back that are different.

North American Auto Equipment notes that most garage lifts used to be built into the ground with a single column. The adjustable arms on these lifts made it possible to raise a wide range of vehicles. They were practical, but their installation and upkeep required a significant investment. They also could pose environmental hazards if hydraulic oil leaked into the ground.

To solve these issues, above-ground post lifts were developed. The central position of the posts, which were initially only available in a symmetrical configuration for some vehicles, made it difficult to enter and exit the vehicle as you positioned it for lifting. For this reason, an asymmetrical lift alternative was developed. This lift can accommodate a variety of automobiles without obstructing the doors.

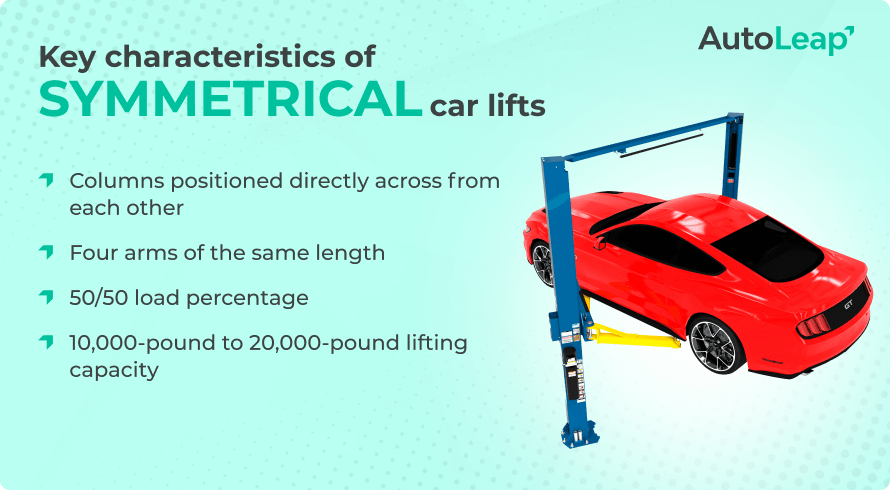

Understanding the symmetrical car lift

All above-ground, two-post lifts were symmetrical when they initially hit the market. This lift’s two poles align directly across from one another, featuring four arms of the same length.

These design qualities put the center of gravity of a vehicle directly between the two poles and in the middle of the vehicle from front to back, with an equal 50% split on both sides. In the center of the entire setup, equal pressure is applied to the lift’s posts and carriage in symmetrical lifts. That layout permits a larger drive-through space in your shop.

This kind of lift is ideal for trucks and vehicles with long wheelbases.

Characteristics that stand out

Landmark Tools notes several symmetrical car lift characteristics that shop owners will appreciate, including:

- Columns positioned directly across from each other

- Four arms of the same length

- 50/50 load percentage

- Overhead or floor plate design

- Support for older, heavier steel vehicles (like SUVs and trucks)

- 10,000-pound to 20,000-pound lifting capacity

- Ease of use functionality

Disadvantages to keep in mind

There are some potential negatives to consider when selecting a symmetrical car lift for your auto repair business.

Due to the placement of the posts, there is a danger of inadvertent damage to your customers’ vehicles, not to mention the inconvenience of not being able to access the interior once hoisted.

Simply put, symmetrical car lifts are less versatile than asymmetrical car lifts.

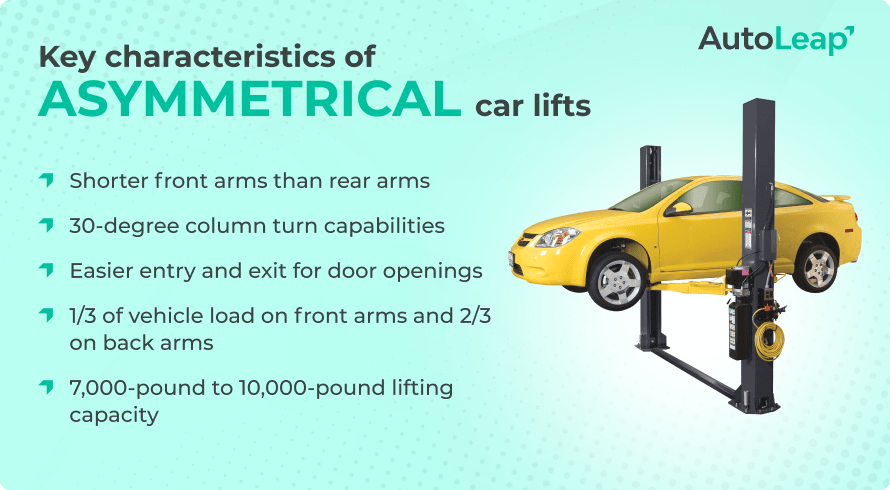

Understanding the asymmetrical car lift

Asymmetrical car lifts differ from symmetrical lifts in the total distance you need to drive over them. This difference exists because the front arms are only a little shorter than the back arms. The columns were turned by 30 degrees in order to correct and balance the vehicles properly.

Characteristics that stand out

Landmark Tools notes a list of defining features for asymmetrical car lifts as well, which includes:

- Designed after the symmetric lift to accommodate lighter-built vehicles

- Features 30-degree turn capabilities in the column – allowing for the vehicle to be offset on the lift

- Allows for easier entry and exit with door openings, minimizing chances of damaged doors from banging against the post

- Load is 1/3 of the vehicle on the front arms and 2/3 of the vehicle on the rear arms

- Lifting capacity ranges from 7,000 pounds to 10,000 pounds

- Front arms are shorter than rear arms

Disadvantages to keep in mind

A few disadvantages exist for shops considering asymmetrical car lifts. Landmark Tools notes that these lifts can specifically pose issues for vehicles with short wheelbases.

Landmark Tools also says that a short-wheelbase vehicle can become unstable and dangerous when an asymmetric lift isn’t centered correctly. Any sudden shifts or movement caused by this instability can pose serious safety risks for the technicians working in your shop.

When choosing a car lift, you need to factor in these details and account for the types of vehicles your business repairs.

Understanding the super symmetrical lift

A more contemporary lift system design, the super symmetrical car lift combines symmetrical and asymmetrical car lift functions to create a flexible car lift solution. Landmark Tools details the design and functionality of this unique lift, noting that its three-stage front arms and two-stage rear arms can be set up to run parallel.

Landmark Tools describes the functionality of a super symmetric car lift. The front arms can, however, be folded down to fit (small automobiles) or fully extended to match the length of the rear arms when lifting vehicles with longer wheelbases thanks to the three-stage setup design. However, it is hardly the most common type of two-post car lift.

Closing thoughts

Choosing a car lift will come down to your shop layout, which vehicles your technicians work on, and your personal preferences. We hope this guide helps you understand the key advantages, disadvantages, and general differences between the industry’s two most popular options.

Demo

Demo