Is your auto repair shop looking to add tire balancing as a service? Without a doubt, it’s a basic utility and great for increasing revenues and profit!

Tire maintenance is a huge priority, as 27% of roadside emergencies are caused by tire issues. Tires have an average life span of six years, yet four out of five individuals do not properly inflate, rotate and balance their tires. By including this additional service, you are doing your customers a huge favor.

Choosing the right tire balancing machine does not need to be difficult. We have curated the perfect guide to help you pick the right car tire balancer.

What is a tire balancing machine?

On the off chance you don’t already know, this piece of equipment helps your mechanics evenly align the wheels’ weight. This ensures that once the tires are mounted onto the vehicle, they rotate smoothly.

The weight of the tire and wheel assembly must be evenly distributed. This distribution helps maintain a smooth ride as they rotate evenly at high speeds. If they are not balanced well, it can cause stress on tire treads and cause the car to vibrate. Eventually, this will lead to increased tire wear and tear.

In essence, the machine helps indicate if there is an imbalance. Your technicians then add wheel weights to correct the issue.

More advanced machines actually tell the mechanic how much weight needs to be added. This technology makes it quick and efficient for both you and your customer.

Balanced wheel assemblies will not only eliminate vibration and wobbling, but increase fuel mileage and reduce stress on the car’s functionality.

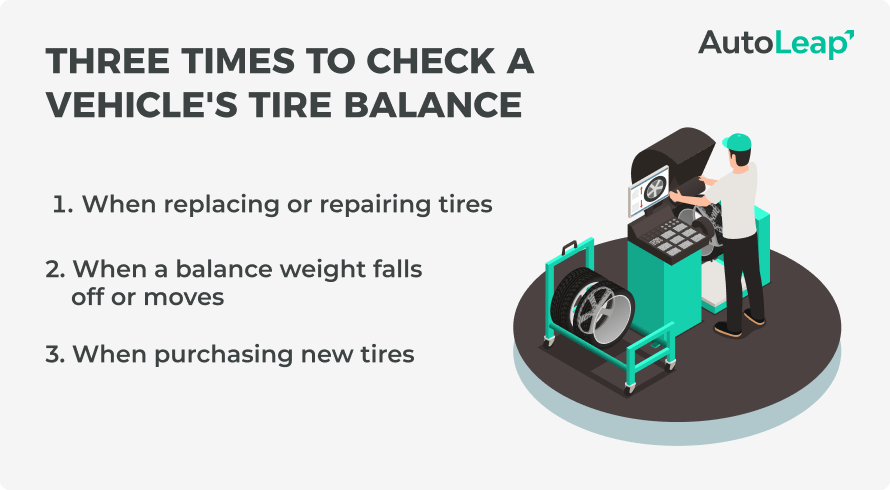

When should you balance tires?

Tires nowadays hold their balance well, unless an external force throws them out of order. One example where this occurs is hitting a curb. Usually out of balance tires cause vibrations at speeds of 50 mph to 70 mph.

Sometimes consumers won’t notice their tires are imbalanced, increasing damage to the wheels and vehicle. All tire technicians know that balancing wheel assemblies are the cure to vibration and wobbling.

Here are three times you should check a vehicle’s tire balance:

Another item mechanics should keep an eye out for are wheel lugs in certain positions. Some of these locking lugs weigh 1.5 ounces heavier than traditional lug nuts. This can cause a half ounce translation on the wheel.

What machine is used to balance tires?

Most balancing equipment has been designed for specific vehicle types. This equipment works for commercial, passenger and even the heaviest vehicles.

There are three different types of car wheel balance machines:

- Dynamic balancers

- Static balancers

- Bubble balancers

More often than not, you will find a dynamic tire balancing machine in high-volume tire shops. However, here is a breakdown of all three. We also explain how to use these tire balancing machines.

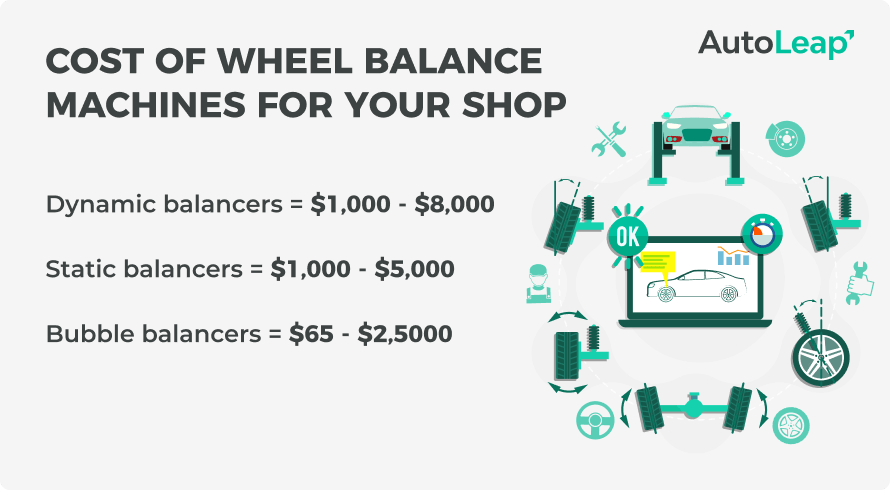

Dynamic balancers

The most accurate of all three options, this balancer requires a bigger investment. The total cost can come in anywhere between $1000 to $8000.

The great thing about this balancer type is that they offer both static and dynamic balancing methods. By offering computer-generated imbalances, it helps you add weight to both the inside and outside of the wheels. This prevents the tire assembly from wobbling during rotation. As a result, your customers enjoy a smoother ride.

The work is simplified for you. All the mechanic really needs to do is mount the tires and attach the corrective weights as instructed by the machine. Voila!

You will find most manufacturers sell dynamic tire balancing machines, as they are efficient and easy to use. Considering it features both static and dynamic methods, you will end up servicing a greater range of vehicles.

Static balancers

This tire balancing machine makes use of gravity to detect wheel weight static imbalance. By mounting the wheel onto a non-rotating spindle, the heavier part of the wheel will automatically rotate to the bottom. This indicates where it is heavier, and where it is lighter.

The machine keeps the assembly on a single plane and adds weight only to the lighter side of the tire. This means that it is best for wheels that take weight mostly on the inside. Usually these are truck and motorcycle tires.

Static balancers tend to be less accurate than dynamic balancers. However, due to its affordability, it makes for a great choice. In total, this balancer can cost between $1000 to $5000.

Bubble balancers

Similar to the static balancers, the portable bubble wheel balancers are the most basic type of equipment.

Just like the static balancer, you mount the tire onto a spindle and gravity does the rest. The spindle has a little bubble in its center. Whichever side of the wheel is heavier will hang lower and the bubble will indicate this imbalance. That is when you will add the corrective weights.

They may require a little more effort as everything is done manually. However, they take up little space and are much more affordable. Additionally, they can weigh as little as 15 pounds.

The cost of these balancers can range anywhere between $65 to $2500.

Type of weights

There are a number of weights you can use for your balancing process. There are various standardized clip-on weights that accommodate different rim flanges.

For instance, there are FN weights for Japanese vehicles, MC weights for most U.S. vehicles, EN weights for VW and Honda cars, and IAW weights for European and South Korean vehicles.

You have adhesive tape-on weights as well. Tape-on weights are used for custom vehicles that do not have an outside flange.

The primary materials used to manufacture wheel weights include lead, zinc and steel. However, several states have outlawed lead weights. Factor that into your consideration.

Frequently asked questions

How much weight should be used to balance tires?

Usually about one quarter ounce on the side that is imbalanced. The tire balancer machine should want it placed either 180 degrees opposite to the previous weight or in the same place.

How do you read a tire balancer?

If it is computational, you will simply check the reader. However if you have a static or bubble balancer, you will see which way the tire is leaning on the spindle – indicating the heavier end.

What is the best type of tire balancing?

Larger, more powerful and with advanced features, dynamic tire balancers are probably the best option. However, static and bubble balancers may not be as accurate but still get the job done.

Do all tires need weights to be balanced?

Absolutely! Without balanced tire assemblies, your tires’ wear and tear increases. You will also experience increased car vibrations while driving. Another key negative is decreased fuel economy.

What size air compressor do I need to run a tire machine?

A 150 PSI (10 bar) is normally sufficient for most automotive applications.

»Looking to transform your shop? Discover how AutoLeap can help.

In conclusion

There you have it. All the basics that you need to purchase your shop’s tire balancing machine.

If you don’t have the budget, starting off with a static or bubble balancer should be your best bet. Over time, as you increase shop revenue, you could think about purchasing a dynamic balancer. That move could help you further increase the volume of your service.