Running an auto repair shop has its fair share of benefits, but it can get a bit tricky at times. Over time as your business grows, you’ll attract more customers and hire more technicians.

During this process, it’s essential to keep track of your labor costs and adjust your labor rate as necessary. In fact, labor times are a key metric that most auto repair shops track frequently.

What is labor time?

Labor is the most important service an auto shop owner can provide, and labor time refers to the hours spent by a technician to work on a car. The billable hours can then be used to determine the total earnings.

For instance, if your hourly labor rate is $200 and a job takes two hours of labor time to complete, your total earnings from labor will be $400, and the labor time for this job will be two hours.

Now that you know what labor times are, you might be wondering how auto repair shops can take advantage of tracking this metric. Let’s delve further to see how.

How do labor times impact your business?

An auto repair shop typically has two major sources of revenue—labor and parts. The profitability of each component is measured using the respective margins.

According to Body Shop Business, parts margins are typically lower than labor margins. When you have an idea about the estimated labor times, you can pay your staff the best wage—whether this is an hourly rate or a flat rate. This is something that works for both your business and the technician, boosts profitability and attracts the best talent in the market.

Giving your technician competitive pay while still charging your customer a fair price is key to running a thriving business. To make getting this balance easier, consider using a labor guide or making a labor matrix specific to your shop’s requirements.

What’s better: low or high labor times?

It might be easy to think that higher labor times are better for your business. After all, the more hours you work on a car, the more money you get, right?

Well it’s not that simple. There are benefits to having extra hours on a car repair estimate, but there are a lot more factors for auto repair shops to consider.

Customers would like to take as few trips to the shop as possible, so a longer one-time service could work in your favor. The benefits of this are:

- For customers: Customers save time and will be happy to get their cars back sooner, which encourages repeat business.

- Business-related: A longer one-time service will be preferable to multiple short trips.

Alan Beech, from Beech Consulting, talks about a 40-40-20 model on his website, where he recommends that for every $1 earned, 40 cents covers your cost of goods sold, 40 cents covers your operating expenses, and 20 cents should be pure profit. This provides a good layout for auto repair shops to plan operations and optimize business performance.

Your average repair time should be short enough to attract customers, yet you can’t compromise on quality. Providing excellent service in a short span of time helps to boost customer retention satisfaction and differentiates your business from the competition.

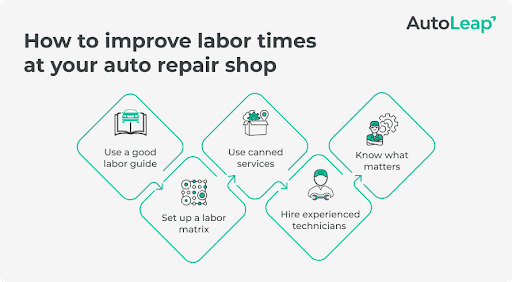

5 tips to improve labor times for auto repair

How do you make sure your auto repair labor times hit that sweet spot where they’re short and effective? Here are some tips to help you get started.

1. Use a good labor auto repair labor guide

If your shop has mechanics that aren’t experienced, an auto repair labor guide can be a good way to set your labor rates and labor time. Rates in guides aren’t standard—they’re estimates for the time and payout for each particular job.Labor guides can offer many benefits to a shop, some of which include:

- Efficiency: Labor guides offer solutions at a glance. You don’t have to do any of the calculations yourself, except maybe adding a multiplier—which isn’t difficult to do, especially if you have the right software.

- Simplicity: Since the rates are highlighted in the labor guide, you don’t have to worry about spending hours with new service advisors about what to quote customers for each job.

If you have a powerful auto repair software like AutoLeap, you can take advantage of labor guides within the app to make your life significantly easier.

2. Set up a labor matrix

Adjusting your labor rates for each repair order manually can be a hassle, especially when you have a large order size. This is where a labor matrix can help you.

Using a labor matrix will allow you to add a multiplier to either your labor hours or your labor rate, resulting in an increased quantity for either metric. This allows you to charge a healthy profit margin to reinvest in your business and continue growing. This is especially helpful when you’re trying to offset losses in other areas of your business.

A labor matrix allows for the relevant margins to be added automatically to car repair estimates once a repair order is made. This is not only faster than inputting the labor rate manually, it’s also most efficient.

3. Use canned services

Canned services at your auto repair shop could be a game-changer. Being able to group certain jobs together so that service advisors don’t have to waste time doing so saves a lot of time, money, and energy. Additionally, it opens doors for you to offer other services that a customer’s car may need.

Imagine your technician is conducting a brake replacement, and the experience that comes from previous repair jobs kicks in. Customers who have had a brake replacement usually get new brake fluid, hoses, etc. Usually a shop would have to input each item separately when making a car repair estimate along with adjusting the labor rate. Here’s how you could split the services up for each metric:

- Labor: This is the labor rate you charge for conducting brake replacements. Some shops charge a flat rate while others have variable pricing.

- Parts: The cost of all parts included is included in this section. All parts like new hoses, pads, rotors, and fluids fall into this category. If you see a damaged hose while replacing the brake pad, you can increase your average repair order size by adding it to the estimate.

You can customize each canned service to suit the relevant auto repair service required regularly. Once the repair jobs are completed, all it takes is one click to get the job done.

4. Hire experienced technicians

No two jobs will be the exact same. A couple of cars may roll in with the same part that needs replacement. But since the make and model of the cars are different, you’ll have to approach each vehicle in a different way. This ends up leading to different labor times on both vehicles.

Here’s how hiring skilled and experienced techs can help:

Accurate results: Techs are often paid per hour, and experienced techs bring the best value. According to a study by Indeed, a mechanic’s average hourly wage in the US is $22 and varies depending on the state you’re in. While experienced mechanics will charge more, you can trust them to get the job done accurately with minimal oversight needed.

- Quick diagnostics: Exposure to fixing vehicles for multiple years during their careers makes it easier to identify problems. Technicians who have been in the field for a few years may identify potential problems by simply listening to engine sounds. Working on larger jobs as opposed to smaller ones is key to being more profitable.

- Time management: People who have been in the field know that it’s more effective to fix a car properly the first time around. If a tech takes apart and reassembles an engine block in record time, only to have it broken at the end, they’re managing their time poorly. Techs with more hands-on experience know how to allocate their time properly and get the job done right on the first try.

- Greater customer trust: A survey by American Automobile Association (AAA) revealed that two-thirds of US drivers don’t trust their mechanics. 63% of the respondents were concerned due to negative past experiences, and 64% singled out a single shop that they do trust. Having an experienced mechanic will help you deliver good service consistently, leading to greater customer retention. Since your techs are familiar with the car, it’ll take less time for them to conduct repairs.

5. Understand factors affecting labor time

There are many factors that you need to consider when calculating labor times—location, vehicle make and model, and technician qualifications to name a few. Having the best understanding of all these factors gives you a complete overview of your business. You can see exactly what you have to work with and make decisions accordingly.

Here are a few key areas to keep in mind when calculating labor times:

- Vehicle make and model: Different cars need to be treated according to manufacturer recommendations, even when they have a similar issue at hand. For two cars coming in for an engine bay inspection, a Toyota Corolla will have a different list of inspection items than a Chevrolet Camaro or a Toyota Tacoma.

Research by IMR Inc. reveals that approximately only 30% of auto repair shops work on electric vehicles (EV) or hybrid engine technology. These shops would have different labor times and rates based on:

- Technical know-how: Working on an EV presents challenges that internal combustion engines (ICE) don’t. Techs need a different skill-set to work on such vehicles.

- Time: The repairs an EV would need differ greatly from what an ICE-powered vehicle would. This indicates that the time required for each job would vary between the two.

Working on EVs may be a worthwhile option for most shop owners considering that it’s a fairly untapped market.

- Nature of the job: Some jobs take longer than others, and shops need to accurately estimate the time for each. Standard times exist for each type of job, as you’ll see in automotive labor guides, but it’s a good idea to give yourself some leeway since you can never accurately predict the circumstances of each visit.

Repair costs generally have a lot of different components to consider, such as shop overhead and labor cost. It’s important to holistically examine each one and see where you can optimize rates to maximize profit without compromising on quality.

Closing thoughts

Making the most out of each available metric should be the key objective for an independent repair shop. Labor will be the key driver of revenue for most auto repair businesses, making it essential to set up a labor matrix and get suitable labor times. Everything from common repairs to specific one-off repair work requires technicians to put in effort.

Make sure the labor rate is reflective of the value provided by technicians, and ensure the final price charged to customers has a healthy balance between business and customer satisfaction.

Most mechanics work a traditional 40-hour work schedule. But some mechanics may work overtime to increase their earning potential.

Shops can use a number of systems to help their mechanics manage labor times. These include:

- Following a auto repair labor guide

- Setting up a labor matrix

- Using canned services

The timing on car repairs can vary. Easier jobs like a simple parts replacement may take an hour or two, while comprehensive engine repairs can take days to complete.

The time it takes to complete body work repairs depends on the vehicle’s damage severity. For minor repairs, it may take one or two days to complete. Extensive damage could take several weeks to address.

Auto mechanics need an advanced skill-set to work on vehicles. These skills include:

- Technical precision

- Problem-solving

- Curiosity