Are you looking for the best tire mounting machine for your auto repair shop? As a proactive shop owner, you want to avoid an ineffective option that exceeds your budget.

There are many factors to consider when choosing a tire mounting machine for your auto repair business. Let’s consider every angle to help you find the perfect fit!

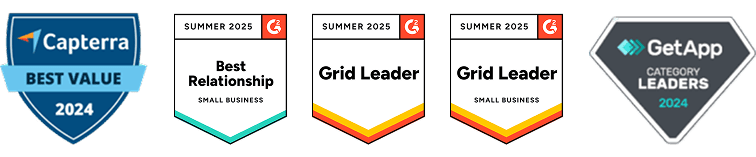

Types of tire mounting machines

Swing-arm tire changers

Popular brands offering this type of tire changer include Hunter Engineering, Corghi, and Hoffman.

Tilt-back tire changer

Touchless/leverless tire changers

Touchless and leverless tire changers deliver functional automation to tire services in your auto repair shop. These machines can make tire changing a breeze and keep the expensive rims you work on safe from scratches and damage.

So, how does this tire changer work? Its automated arms and precision-controlled mechanisms will ensure a perfect fit across various tire types. Gone are the days of your techs wrestling with tires using pry bars and levers.

With these high-tech machines, your mechanics no longer have to worry about causing manual damage to delicate wheels. The touchless changer handles tires smoothly and quickly, turning a once-manual responsibility into a streamlined service.

Touchless tire changers are the future, making every auto shop’s dream of effortless, top-notch service a reality. Some quality brand recommendations for touchless tire changers include Hunter Engineering and Corghi.

Heavy-duty tire changers

Heavy-duty tire changers are the unsung heroes of auto repair shops. That’s especially true for shops handling big, rugged tires on trucks, buses, and other commercial vehicles.

These powerhouse machines take the grunt work out of changing tires for heavy-duty vehicles. With their advanced features, they can support mounting and demounting for commercial-size tires. Advanced mounting and bead-breaking technology saves your techs considerable time, meaning one less labor-intensive service in the shop.

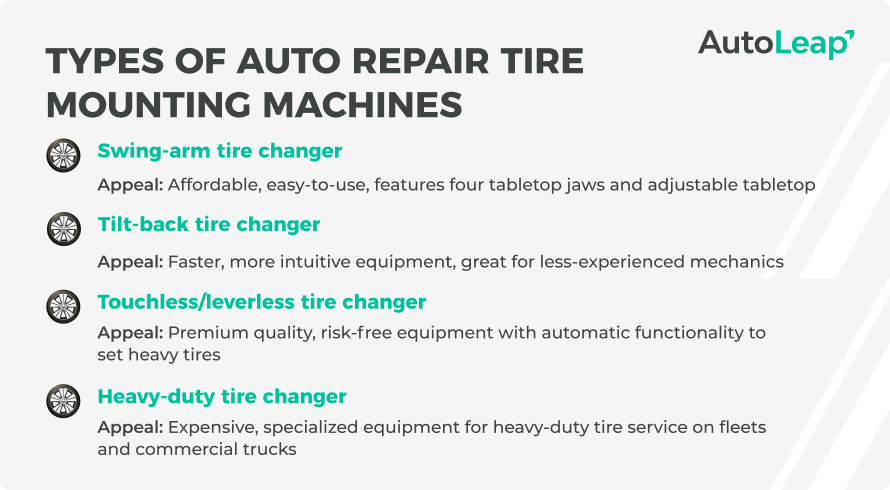

Tips to keep in mind

- Assess your needs: Consider the types of vehicles and tires your shop services. For example, if you only work with small sedans and SUVs, find a tire changer that supports these models. But don’t expect that same tire changer to support service work on larger trucks and commercial vehicles.

- Consider future growth: Choose a tire changer that meets your shop’s needs while also supporting your future business growth. Think about the potential expansion of your tire services or increased customer volume.

- Evaluate features and technology: List the tire changer features and technology that matter most to your business. Specifically, prioritize features to improve your techs’ efficiency while ensuring safe work in your service bays. Then begin your research on the most popular machines equipped with these features.

- Prioritize durability and reliability: Opt for brands known for their durable designs and strong marketplace reputations. A tire changer is a significant financial investment, so choosing a machine built to last and backed by good customer support is essential.

- Check compatibility: Ensure the tire changer is compatible with the types of tires and wheels your shop works with most often. That may include run-flat tires or large-diameter wheels. But this consideration will be shop-specific.

- Evaluate your space: How much space do you plan on reserving for this machine? Assess the overall room available in your shop. Ensure the tire changer fits in this allocated workspace without obstructing other service operations and overall technician safety.

- Account for ease of use: Consider your technicians’ training and skill level. Your tire machine should feature a user-friendly interface and straightforward operation to reduce training time and minimize potential human errors.

- Ensure customer support: Look into the after-sales support and warranty that the tire machine’s manufacturer offers. Access to reliable customer service is crucial for minimizing your techs’ downtime and maintaining shop productivity.

- Confirm budget and ROI: Budget is an important consideration. But go one step further! Focus on the long-term return on your investment. Don’t just immediately cross an expensive tire changer off your list. If you can project a substantial increase in your shop’s efficiency on tire services that will pay off the machine quickly, it may be well worth paying up for.

- Do your research: The more detailed a research process, the better! Learn as much as you can about the most reputable brands. Ask partners you have at other shops what tire changers they trust. Read as many third-party online reviews as you can.

Final note

With so many tire changer brands in the marketplace, it’s essential to understand what really matters as your shop weighs the pros and cons. We hope this guide helps you find a quality machine that suits your shop’s tire service goals!

Frequently asked questions

1) Can you make money with a tire machine?

Successful auto repair shops can generate thousands of dollars in monthly tire service revenue. If done correctly, your shop can open up a reliable new revenue stream when offering this service.

2) What should I look for in a tire changer?

Many factors matter when considering a tire changer for your auto repair business. You will need to consider the types of tires you work on, the machine’s durability, ease of use, and available space for its safe operation within your shop.

3) How do you use a manual tire change machine?

Using a manual tire changer involves securing the wheel on the changer’s base, breaking the bead with the bead breaker tool, and then using tire irons or bars to pry the tire off the rim and install a new tire. Following the steps and safety precautions detailed in your machine’s manual is essential for effective and safe tire changing.

4) How many amps does a tire machine use?

The amperage draw of a tire machine can vary widely depending on its size, design, and features. But on average, a tire changer might use 15 to 20 amps. Always refer to your specific machine’s manual for precise requirements.

5) Are tire machines 220V?

Many tire machines, especially those designed for professional use in auto repair shops, operate on 220V power. However, the exact voltage can vary by model and manufacturer.

6) What size air compressor do I need to run a tire machine?

You will typically need an air compressor that can deliver at least 4 to 5 CFM (Cubic Feet per Minute) at 90 to 150 PSI (Pounds per Square Inch). However, exact requirements can vary based on the specific tire changer model and its operational demands.