Storing parts in a warehouse frees up space to store more high-value equipment in your shop. However, you can’t just chuck parts in there and call it a day—it’s important to have structure in your storage solutions. Otherwise, you’ll end up mixing up parts, and become confused about whether the part is in stock or not. But don’t worry, here’s how the latest in auto mechanic software can help you manage your warehouse stock effectively.

Step 1: Navigate to the Inventory section

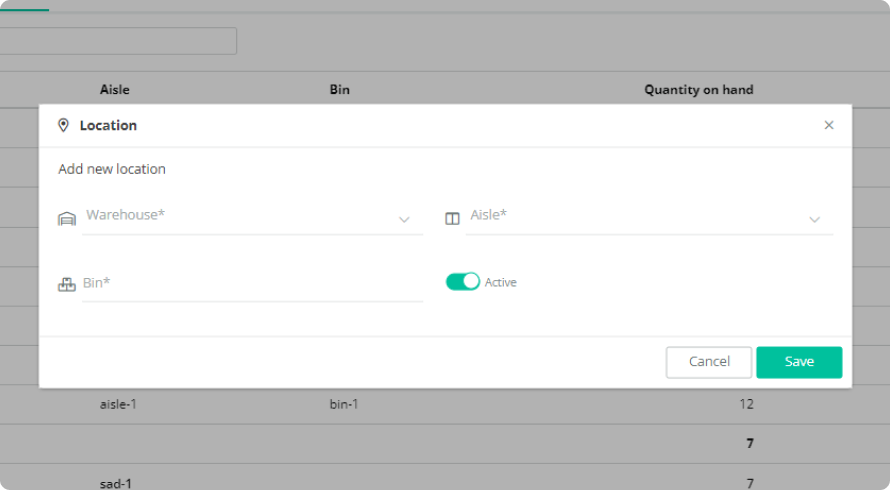

Step 2: Add a new warehouse

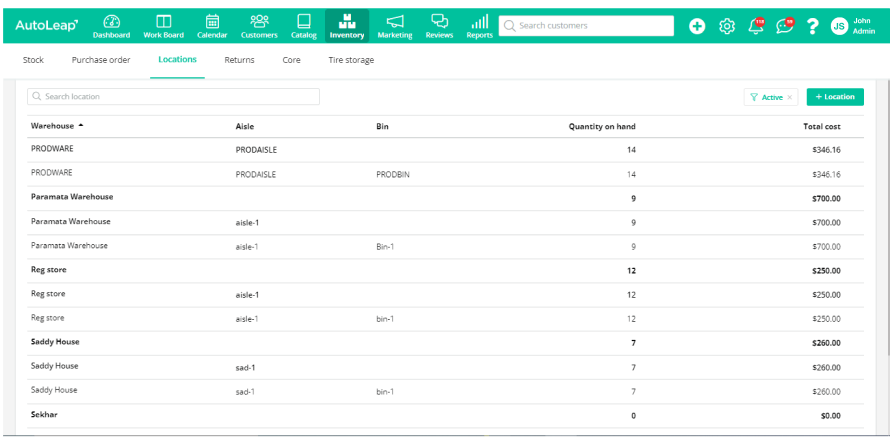

To add a new warehouse location to your environment, click the “Locations” tab under the green ribbon. From there, you will see a screen appear like the one shown below.

Step 3: Add parts to the warehouse

There are currently two inventory items that you can assign to your warehouse—Parts and Tires. Any parts order you make will have an option that allows you to add the part to the warehouse directly. For existing parts, you can navigate to the “Parts” function in the “Catalog” menu and click on a part to see the details. Scroll down to the warehouse location and you can move your part into the warehouse from the drop-down menu. It’s that simple!

Once you have assigned parts to a warehouse, you can select a warehouse from the “Locations” menu in the “Inventory” tab to see the exact type and quantity of the parts in that warehouse.

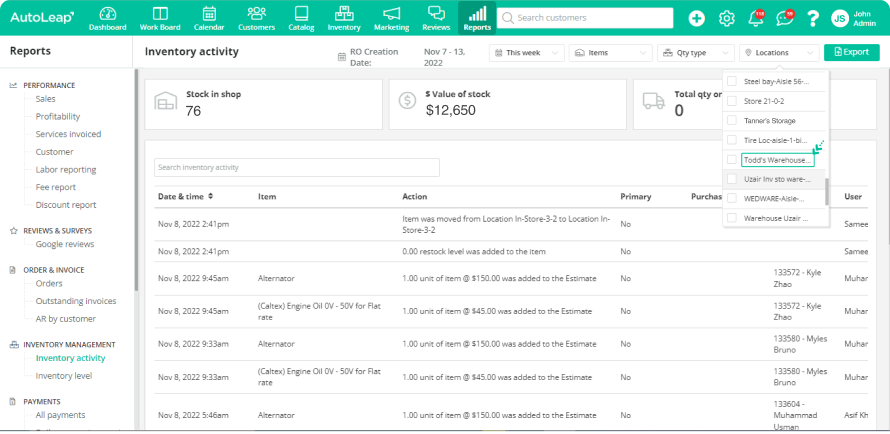

Take inventory reports for example. If you want to see performance metrics for this specific warehouse, simply navigate to a regular report and on the top right corner in the “Locations” tab, you can select the warehouse you want to monitor.

Closing thoughts

Tracking inventory levels in warehouses has never been easier with AutoLeap’s state-of-the-art features. Follow this step-by-step advice to streamline how your shop manages its warehouse inventory.