Did you know as an auto repair shop owner, you and your employees must follow Occupational Safety and Health Administration (OSHA) regulations?

Following these regulations will ensure you run a compliant business that safeguards the well-being of its team. Let’s review some of the key regulations and best practices for your shop.

Schedule a free demo today!

Boost your shop sales

Simplify shop management

Empower your technicians

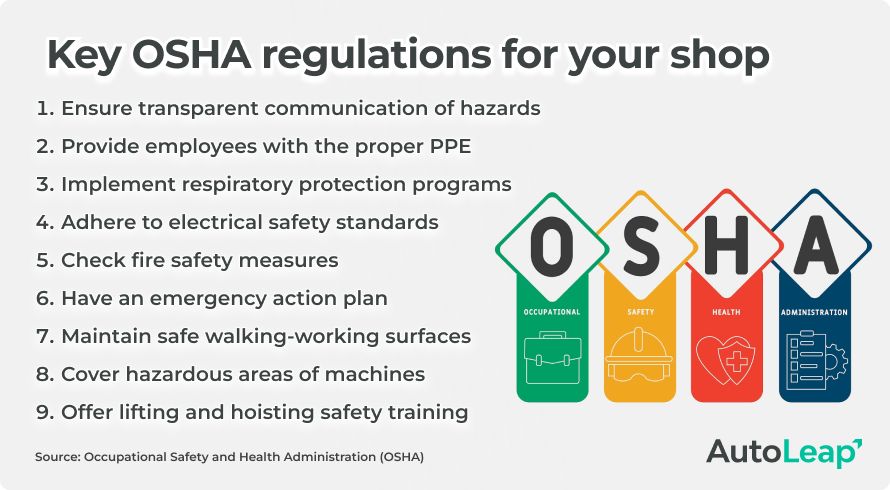

9 core OSHA regulations for auto repair shops

OSHA is a federal agency. It is a part of the United States Department of Labor. And its primary purpose is to ensure “safe and healthful working conditions,” according to OSHA.

OSHA outlines a few auto repair shop regulations. Let’s study them in detail.

1) Ensure transparent communication of hazards

One of the OSHA regulations for auto repair shops is effective hazard communication. According to its website, this means:

- Proper labeling of hazardous materials

- Creation of safety data sheets (SDS)

- Training employees to understand and handle these materials

The SDS gives information about ‘health hazards, environmental and disposal concerns, and protective measures against each chemical.’ According to OSHA’s website, all shops must keep the SDS for each hazardous chemical in a known and accessible location.

2) Provide employees with the necessary Personal Protective Equipment (PPE)

According to auto repair shop regulations set by OSHA, your shop must provide appropriate PPE. But compliance isn’t satisfied there. Additionally, you have to encourage using PPE among your techs and relevant team members.

This will reduce the risks involved with various tasks in the repair process. Examples of PPE include eye protection, gloves, and hearing protection.

Eye protection

Your auto technicians need protection against chemical splashes, flying sparks, or harmful glare. So, the eye protection you provide must be fit for the specific work.

For example, if your auto technician uses power tools, they need eye protection. Power tools such as drills and saws generate high-speed movements. Eye protection is necessary to shield against potential flying objects or debris.

Gloves

Auto repair technicians handle various tasks that expose their hands to potential hazards. Thus, using gloves is essential for protection. For example, many auto repair tasks involve using chemicals, including lubricants, solvents, and cleaning agents. Wearing gloves protects your techs from skin exposure to corrosive or harmful substances.

They will also need leather gloves for welding and fabricating metal components. These protect against burns and provide a barrier against sparks.

Hearing protection

Your auto repair technicians often deal with high noise levels during various repairs. Therefore, they have to use hearing protection to prevent long-term hearing damage.

Take the examples of drills and grinders. These tools can get loud, especially in a confined service bay. This makes hearing protection crucial to prevent noise-induced hearing loss.

3) Implement respiratory protection programs

In an auto repair shop, there is also the risk of potential exposure to harmful fumes and airborne particles. For that reason, a respiratory protection program has to be put in place.

According to the Office of Technical Assistance and Technology, your shop’s program should include:

- Written workplace procedures

- Proper selection of NIOSH-approved respirators

- Fit testing and training (required for those who wear tight-fitting respirators)

- Medical evaluations

- Work area surveillance

- Clean breathing air when using supplied air respirators

4) Adhere to electrical safety standards

Your auto repair shop relies on various electrical systems. These include power tools, diagnostic equipment, and lighting. Standard electrical systems include lighting fixtures, power outlets, and electrical panels. There is specialized equipment, too, such as battery chargers and welding machines.

For the safety of personnel and the facility, implement OSHA’s electrical safety standards:

- Regular inspection and maintenance of electrical systems: These steps will help you identify potential hazards like frayed wires or faulty connections

- Proper grounding practices to prevent electrical shocks: Your shop also needs fuses and circuit breaker protection devices.

- Employee training on lockout/tagout procedures: This training will help your techs isolate electrical systems during maintenance or repairs.

Implementing these safety standards carefully will protect your auto technicians from potential electrocution. They will also protect your facility from electrical fires and equipment damage.

5) Check fire safety measures

Auto repair shops are prone to fire risks due to flammable liquids or welding activities and electrical systems. This means you have to:

- Store your flammable materials

- Provide fire prevention training for employees

- Equip your shop with fire extinguishers

The U.S. Fire Administration requires all buildings to carry fire extinguishers. To comply, these fire extinguishers need:

- Annual maintenance

- Labeled month and year of last maintenance date

- Visible and accessible location in the shop

- No leaks, damage, or clogged issues

6) Have an emergency action plan

OSHA requires every auto repair shop to have a well-defined emergency action plan. This plan should encompass procedures for evacuation, emergency shutdowns, and first aid.

Additionally, carry out regular drills and employee training. These will ensure a swift and organized response in case of emergencies.

7) Maintain safe walking-working surfaces

According to Evarts Tremaine, your auto repair shop must have safe walking and working surfaces to achieve OSHA compliance. This precaution will help prevent slips, trips, and falls. Keep your floor clean and free of clutter. Review your shop layout for potential obstacles and adjust as needed.

8) Cover hazardous areas of a machine

According to OSHA, moving machine parts can sometimes cause severe injuries, such as finger cutting, burns, or blindness. OSHA defines machine guarding as installing physical barriers, presence-sensing devices, and other safety measures in your shop. These prevention steps will help your techs avoid accidental contact with moving parts. Your auto repair shop needs established procedures for machine guarding in place.

9) Offer training on lifting and hoisting safety

Auto repair shops often involve heavy lifting and hoisting activities. For this reason, it’s critical to train your technicians on proper lifting techniques and the safe use of mechanical aids.

Carry out regular inspections and proactive maintenance of your lifting equipment. You must complete these reviews regularly, as their condition and safe functionality can change with excess use over time. A thoughtful plan in this area will help your shop achieve OSHA compliance and maintain a safe working environment.

Implementing OSHA's automotive shop regulations

We covered some of the top OSHA regulations in detail. Now, it’s time to put these regulations into practice!

Auto repair shop owners and their managers can take the following steps:

Conduct a comprehensive safety audit

According to KPA, begin by conducting a thorough safety audit of the entire facility. Focus on:

- Identifying areas where hazards could occur

- Assessing the effectiveness of existing safety measures

- Prioritizing areas that need immediate attention

Create a safety committee

OSHA recommends establishing a safety committee in your auto repair business. Involve both management and employees on this committee. This creates a collaborative approach to safety.

Furthermore, you can schedule regular meetings to discuss:

- Safety concerns

- Review incidents

- Put in place corrective actions

Use OSHA resources

Take advantage of the resources provided by OSHA. OSHA’s website offers specific guidelines and checklists. It also offers educational materials tailored for auto repair shops.

These resources cover critical safety areas. Plus, they provide practical guidance for identifying and addressing potential hazards.

Develop Standard Operating Procedures (SOPs)

According to the training requirements set by OSHA, draft clear and concise SOPs for all critical processes in your auto repair shop. This includes:

- Hazardous materials procedures

- Using machinery

- Responding to emergencies

Make SOPs readily accessible to employees

OSHA regulations may evolve, and so should your safety protocols. Stay informed about any updates to OSHA guidelines. Adjust your safety measures accordingly. Review and update SOPs to reflect the most current best practices.

Invest in safety equipment and infrastructure

Set aside a budget to buy and maintain your shop’s safety equipment. This includes PPE, fire extinguishers, first aid kits, and safety signage for display in your service bays.

When expiration dates arrive, ensure you replace the equipment. Even before those dates, create a cadence for inspecting and maintaining your safety supplies.

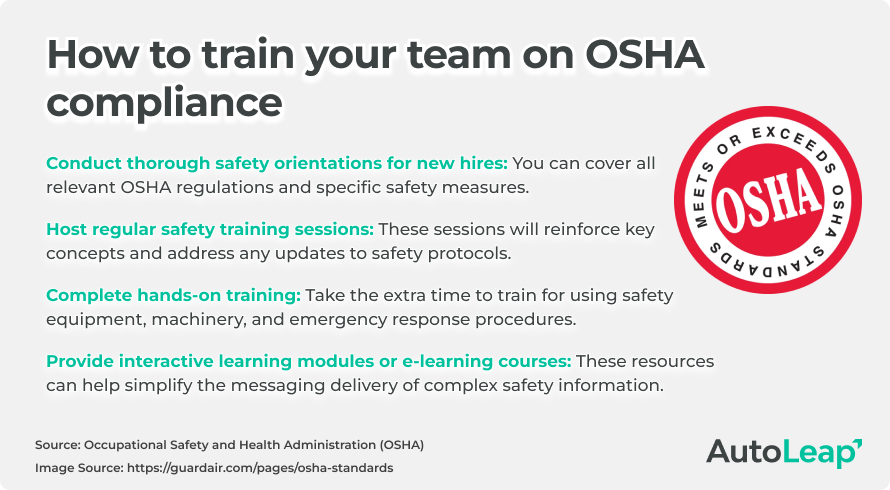

Training and education for compliance

It’s training time! As a shop owner, it’s critical that you invest in regular training programs for your employees. After all, OSHA has set strict training standards for auto repair shops.

Educate your employees on OSHA regulations, safe work practices, and the proper use of equipment. If each team member is well-informed, it contributes to a safer workplace.

This training and education program can include:

You can also maintain detailed records of your employee training. Include dates, topics covered, and individual attendance. This documentation will serve as evidence of compliance in the case of an OSHA audit of your business.

And, of course, you must carry out periodic refresher courses. This will help employees stay informed and vigilant about safety practices over time.

According to OSHA, training is for more than just employees. It’s also for top management, supervisors, and safety and health specialists.

The consequences of non-compliance

Non-compliance with OSHA regulations may result in fines and legal actions for your business. It can also compromise the safety of employees and customers in the shop.

By adhering to auto repair shop regulations, you protect your workforce. You also build a reputation for reliability and responsibility within the community.

Here are a few consequences for non-compliance:

Financial penalties

Your auto repair shop can receive fines from OSHA for non-compliance in one or more areas we covered. According to OSHA, the penalty can go up to $70,000. And it is not less than $5,000. The severity of your business’s infractions will determine what you owe.

Legal consequences

Persistent non-compliance may lead to legal action, according to COTNEY. These punishments can involve lawsuits and court proceedings.

Workplace incidents

Workplace accidents and injuries can occur, especially if you don’t comply with OSHA regulations. This may lead to potential worker compensation claims and increased insurance costs for your business.

Reputational damage

Non-compliance can also tarnish the reputation of your auto repair shop. Customers will always prefer businesses that focus on safety. Any negative publicity can result in losing your existing clients and potential new business.

Wrapping up

Prioritizing safety is not just a legal requirement, it’s a moral obligation. Your auto repair shop must create a thoughtful plan to abide by these OSHA regulations.

Compliance will create a safe yet efficient environment for your shop’s employees. Even better, your customers can trust the service you provide.

To support both operational efficiency and proactive communication, many auto repair shops now use AutoLeap’s shop management system. Beyond just scheduling and invoices, it offers structured workflows and inspection logs that help you stay organized, so safety and compliance become a natural part of your daily routine.