Remember when you could order car parts, and they’d arrive in an hour or two? Now, it takes a couple of days or even weeks to get a simple item like an oil filter. Instead of servicing vehicles, auto repair shops are spending more time scouring websites for components.

Due to the parts shortage, even General Motors temporarily stopped equipping some 2022 vehicles with heated seats and steering wheels. When major manufacturers have to take shortcuts with their most popular features, you know the problem is big.

Unlock powerful tools to manage your shop. Get the full AutoLeap experience today.

Who’s to blame? Is it just the pandemic? What’s behind the automotive microchip shortage? We answer these questions in this article, so read on!

Reasons behind the auto chip shortage

Pandemic dents supply chain

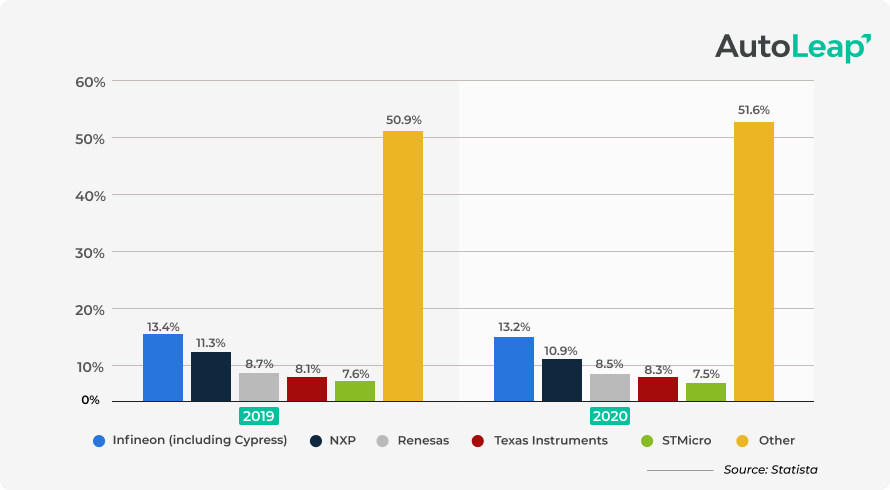

The pandemic caused entire factories to shut down, temporarily or permanently. As people worked from home, there was an unexpected surge in demand for high-tech products. While dropping temporarily in 2019, chip sales surged 29.7% between August 2020 and August 2021 and are predicted to grow another 10% in 2022.

- Manufacturers like giant Taiwan Semiconductor Manufacturing Company (TSMC) and Samsung are building new factories, but it’s expected to take them a few years to get up to speed. Additionally, with the ever-increasing demand for new chips, it might be a while before you get your hands on the latest auto repair equipment or even parts that require complex systems.

- While all of us were stuck at home, factories experienced periods of little to no activity as safety precautions were put into effect to limit the spread of the virus. These factory closures materially impacted chip production.

- TSMC is among one of the few major suppliers of automotive chips. However, the company produces more chips for smartphones compared to vehicles, adding to the auto sector’s suffering.

Weather and disaster

Texas was hit by storms in 2021, resulting in three TSMC factories shutting down. Meanwhile, Taiwan experienced its worst drought in 56 years, ending in June 2021. Chip manufacturing requires a lot of pure water, leading to a lower output during the drought. It’s not until 2022 that supply is predicted to finally meet demand.

In Japan, automotive semiconductor manufacturer Renesas Electronics experienced a fire that destroyed 600 square meters of the factory while ruining 23 machines and making the environment in the cleanroom unsuitable for manufacturing chips. The company produces chips for Japanese automotive firms like Toyota and Honda, and the fire further strained the supply chain.

Materials are scarce and pricey

Even without the chip famine, other problems have recently plagued the automotive supply chain. There’s a scarcity of raw materials like steel, aluminum, rubber, and thermoplastic resin, resulting in volatile pricing and poor parts availability. To make matters worse, container ships are stuck in ports because of labor shortages.

Without a sufficient supply of semiconductors, the entire automobile industry is impacted. Car manufacturers and dealers are low on inventory. Consumers don’t want to wait months for a new car, and many are hanging on to their current vehicle, which is getting older and will require service. That means more business for your shop—as long as you can get the parts you need!

Dealing with the shortage at your auto repair shop

1. Communicate with customers

- How many ways can customers get in touch with you?

- Have you optimized all your platforms to encourage communication?

- What’s the average amount of time you take to respond to queries?

- Are you finding out what services customers are interested in?

In situations where a service or repair will be delayed due to shortages, keep your customer informed. No one wants to hear their car won’t be ready as planned, but you’ll earn trust for being transparent. Communicate with customers through their preferred medium—text, email, or phone call. It’s also important to deal with unhappy customers tactfully, since they may not understand why repairs are being delayed.

Many modern auto repair software have customer communication and scheduling tools built in. You can use these to predict which customers will come in and what jobs are planned for them. For instance, you may have data about a job a customer deferred to the next month, giving you ample time to procure the parts needed for the job.

Free Strategies to Tackle Technician Shortage eBook

Solving the auto repair technician shortage: Discover effective strategies to recruit and keep skilled technicians!

2. Align with suppliers

Let them know as soon as you need a part, and get a timeline for the delivery. Here’s where your automotive repair shop software can really shine in providing the best communication channels. Lead times are going to be inconsistent, but if the channels of communication are open and your suppliers are responsive, you’ll be that much further ahead.

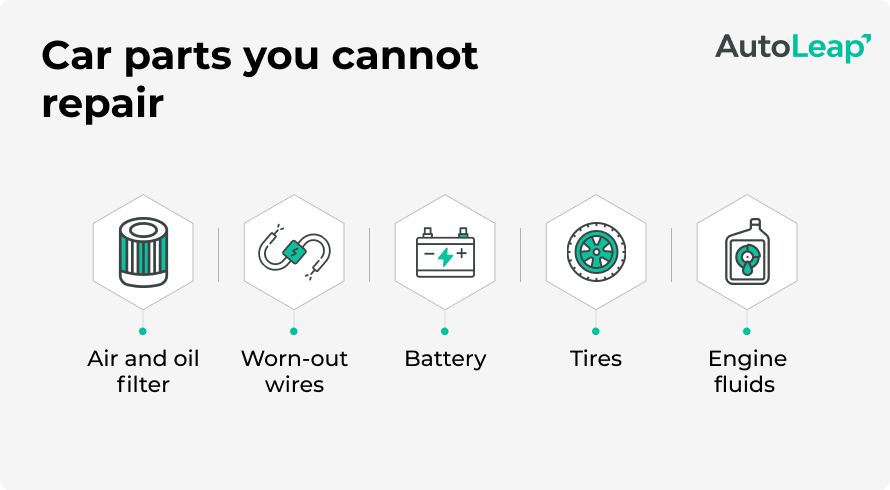

3. Repair versus replace

4. Stock up when possible

Ask your suppliers to let you know if there are parts that you may not need right now but could use in the future. An auto repair shop software can help you determine what services you’ve provided in the past to get an idea of what parts you use most. Additionally, it can also provide information about inventory levels and allow you to restock when parts are running low so you can cut your lead time.