Effective inventory management is a crucial factor for the success of any business. This is especially true for auto repair shops, which depend on having the right components to complete repair orders.

Repair shop inventory management can be a challenging task. It becomes especially difficult if you’re dealing with different suppliers and part categories.

We will discuss effective strategies that auto repair shop owners can use for repair shop inventory management. Let’s dive into our tips for categorizing your auto repair shop’s inventory!

What makes inventory management crucial for your business?

A well-managed auto repair shop inventory list makes your work more efficient. It also helps you create a reliable relationship with your customers. Most importantly, it helps your business grow!

Here are a few factors that make managing your auto repair shop’s inventory crucial:

You can stay ahead of the competition

We don’t have to tell you how competitive the automotive repair industry is. Customers know this too! They’ll take their business elsewhere if you have a delayed order on the part their vehicle needs. “We apologize for the inconvenience” won’t cut it.

Your business runs smooth

Not staying on top of your parts inventory can cause confusion and delays. Your shop will deal with more unhappy customers and lose out on potential business. A lack of organization can even cause unnecessary rifts between your technicians and management!

Everyone wants to do their job well while providing the best experience for their customers. Not having a clear idea of where you stand with your auto repair shop’s inventory will cause systemic problems throughout the workplace.

It allows you to prepare for the worst

Living in a post-pandemic era, we’re more than familiar with how much disruption a small rift in the automobile supply chain can cause. COVID-19 taught us to prepare, plan, and keep our inventory (especially the essential and most used products) stocked up. A business version of a doomsday bunker, if you will.

How can you effectively manage your auto repair shop inventory?

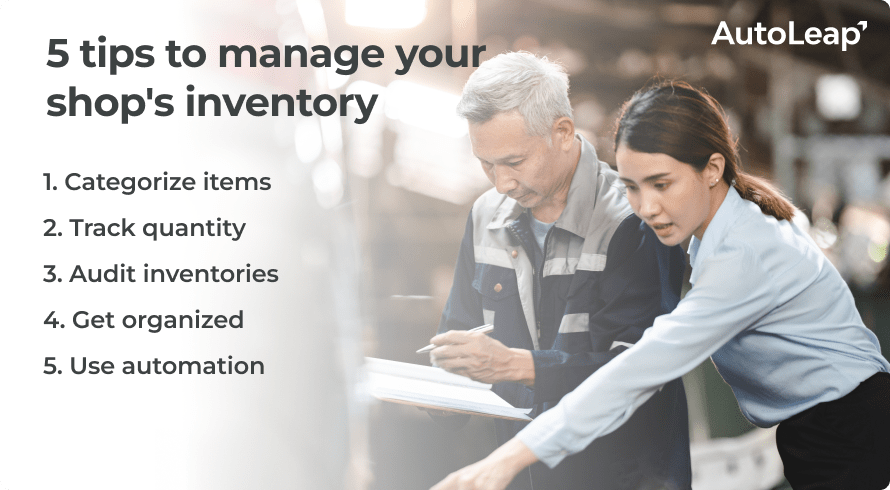

You can manage your auto repair shop’s inventory in many ways. Here are five essential steps to get started!

- Categorize inventory: Categorizing your inventory will help you prioritize your parts. You will also understand which parts to address at specific levels to avoid stockouts. This includes deciding on thresholds for each item.

- Stay on track by keeping track: Monitor your usage to ensure you order the right quantity of items. You can manage this by tracking your orders and stock.

- Conduct regular audits: Conduct regular audits of your inventory. Note any discrepancies found and develop an action plan for addressing them.

- Get organized: You can’t manage a cluttered inventory with precision. Create a detailed plan to ensure every part goes where it needs to be. Document this organizational plan.

- Consider automation: Consider using auto inventory management system like AutoLeap. Technology can provide automatic notifications when a part’s supply is running low. You can even place automatic orders when it hits a designated threshold.

Let’s explore each tip for effective auto repair shop inventory management!

1) Categorize your inventory

Inventory categorization is the first step in efficient repair shop inventory management. This entails classifying every aspect of your inventory, from tires to brakes and engine parts. You can organize this inventory and make it simple to track.

Categorizing your inventory will help you determine which parts are more and less commonly used. Organizing into categories will also make it easy to count the amount of parts you have in stock.

Because you can count each category separately, there is less chance of duplicate counting or missing items. Additionally, inventory categorization makes it simple to rearrange things as necessary.

2) Set up a tracking system

You may manage your inventory by using tracking systems like barcodes or RFID tags. These systems give an identification number to each item in your inventory. You can then use a mobile device to scan or read this identifier to track where each item is and how many you have on hand.

Errors can happen if you mislabel parts. But you can reduce this risk with tracking. This system can also simplify finding things when you need them. For instance, you can locate a brake part using your mobile device and find its exact location in the shop’s inventory when a repair order calls for it.

3) Conduct physical inventory counts

Physical inventory counts are an essential part of effective inventory management. This involves counting each item in your inventory and comparing it to what’s recorded. You can use inventory management software for this. By doing so, you can identify any discrepancies or issues.

Your team can conduct physical inventory counts once a month or quarter. Software automation reduces the need for these physical counts, but it’s still the best practice and advisable.

You can also conduct counts as needed, such as when inventory levels fall below a certain threshold. Regardless of how often you complete physical inventory counts, ensure you are accurate and consistent.

Easy inventory audits can help save you money by:

- Preventing overstocking

- Preventing understocking

- Preventing inaccurate estimates

4) Organize your storage space

Organizing your storage space is another factor in effective inventory management. This means storing items based on frequency of use and size.

This approach helps you focus your inventory management efforts on the most important items. As a result, you can reduce costs and maximize profitability. An organized storage space is an efficient storage space!

5) Use inventory management software

Auto repair shops can use inventory management software as a powerful tool. It can assist you in monitoring your inventory levels, order history, and sales information. Additionally, it can automatically reorder when stock levels drop below a predetermined level. By doing this, you can save time and avoid the annoyance of running out of stock for a crucial item.

You may create alerts and messages for when you need to reorder items with inventory management software like AutoLeap. Think about how much easier it would be to keep track of your inventory and replenish your parts well in advance!

AutoLeap also allows you to create reports showing parts you order frequently and parts you rarely order. As a result, you can lower the amount of inventory you need to hold and increase your inventory levels. You can do this check on every order you need to complete. AutoLeap enables you to track the criteria for each order while keeping you informed on progress.

Closing thoughts

Effective inventory management is essential for auto repair shops! It ensures you have the right parts to meet customer needs, all while minimizing waste and reducing costs!

With the right approach, you can categorize your inventory, establish thresholds, keep accurate records, order from reliable parts suppliers, and conduct regular audits. All these functions will help you organize on the inventory front and maximize your profitability!

FAQs

How do you manage inventory in a shop?

In simple terms, you can manage inventory in your auto repair shop by:

- Assessing what you have on hand

- Reviewing what is sold out

- Analyzing your sales

- Identifying products to reorder

How do small shops manage inventory?

When it comes to a small business, you can manage inventory by:

- Keeping an eye on forecasting

- Going by the first in, first out method (FIFO)

- Identifying stock that’s low in demand

- Applying regular audits

- Using a cloud-based inventory management software