In today’s fast-paced automotive industry, staying ahead means keeping up with the latest diagnostic tools and technologies. For auto technicians, this isn’t just about convenience—it’s about efficiency, accuracy, and the ability to tackle increasingly complex vehicle issues. Let’s explore the future of automotive diagnostic tools and what technicians need to know to stay competitive.

Schedule a free demo today!

Boost your shop sales

Simplify shop management

Empower your technicians

The evolution of diagnostic tools

Diagnostic tools have come a long way from their humble beginnings as simple code readers. As vehicles have become more sophisticated, so too have the tools to diagnose and repair them. There has been a rapid evolution in recent years, with innovations such as wireless scanners and integrated diagnostic systems revolutionizing the way technicians approach vehicle diagnostics.

One notable advancement is the rise of digital vehicle inspection reports in modern shop management systems, which streamlines the inspection process and provides comprehensive digital records.

Emerging technologies in vehicle diagnostics

The landscape of vehicle diagnostics is rapidly evolving, driven by cutting-edge technologies that promise to revolutionize how auto technicians approach repairs.

From artificial intelligence predicting maintenance needs before they arise to augmented reality aiding in visual diagnostics, these emerging technologies are reshaping the future of auto repair. Understanding their impact is crucial for technicians aiming to stay ahead in an increasingly tech-driven industry.

Artificial intelligence and machine learning

AI transforms diagnostics by predicting potential issues before they manifest based on data analytics and pattern recognition. This is prominent in brands such as Tesla, BMW and Mercedes-Benz.

Augmented reality (AR) in diagnostics

AR overlays digital information onto real-world environments, enabling technicians to visualize complex systems and repairs in unprecedented detail. This is a rising trend, especially in brands such as Porsche, Audi, and BMW.

Internet of things (IoT)

IoT devices connect vehicles to the Internet, provide real-time sensor diagnostic data, and improve fault detection accuracy. This can be seen in General Motors’ systems, such as OnStar and GM’s Connected Services, and with Ford’s system, FordPass.

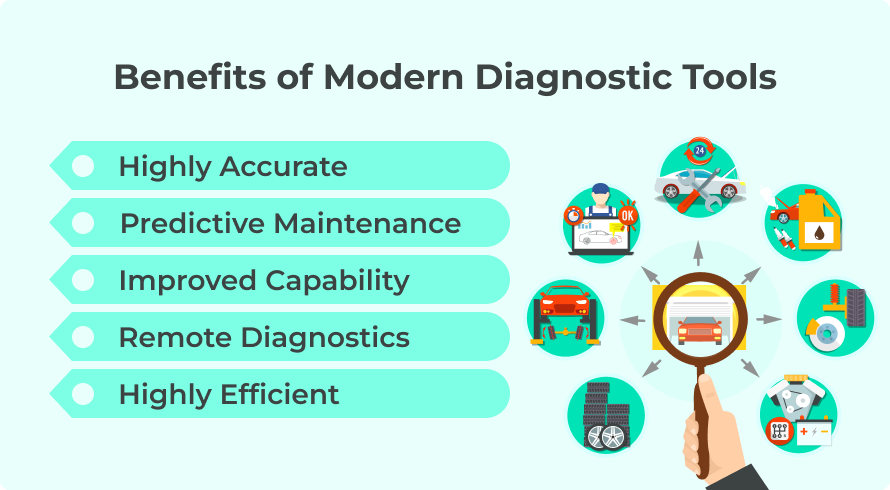

Benefits of modern diagnostic tools

Modern diagnostic tools are a game-changer for technicians and service centers in the automotive repair industry. They bring numerous benefits, such as making operations smoother, improving accuracy, and giving technicians the ability to handle intricate vehicle systems more efficiently.

Let’s explore how these tools reshape the automotive service sector and why they are crucial for staying ahead in this fast-changing field.

- Enhanced accuracy: Advanced diagnostic tools can pinpoint issues more precisely, which reduces guesswork and improves repair effectiveness.

- Efficiency: Streamlined diagnostic processes save time, allowing technicians to diagnose and resolve issues faster, which minimizes vehicle downtime.

- Improved capability: These tools can diagnose increasingly complex hybrid and electric vehicles.

- Remote diagnostics: Some tools enable technicians to diagnose problems remotely, which is convenient for fleet management and reduces the need for in-person inspections.

- Predictive maintenance: Utilizing technologies like AI and IoT, these tools can predict potential issues before they escalate, helping prevent breakdowns and costly repairs.

Challenges and considerations

Using modern diagnostic tools in automotive repair presents challenges that technicians must navigate. These include the learning curve on how to use new technologies effectively, manage costs, ensure compatibility across various vehicle types, safeguard data privacy, and comply with industry regulations. These factors influence how these tools are adopted and integrated into everyday operations.

Here are five key challenges and considerations:

- Learning curve: Technicians need ongoing training to use new diagnostic technologies effectively.

- Cost of technology: Investment in advanced tools can substantially affect budget allocations.

- Compatibility issues: Ensuring tools work seamlessly across different vehicle brands and models is crucial.

- Data security: Protecting sensitive vehicle data transmitted during diagnostics is a growing concern.

- Regulatory compliance: Adhering to evolving industry standards and regulations complicates tool adoption and use.

The impact on repair shops and technicians

As diagnostic tools continue to advance, they are reshaping the landscape of automotive repair, influencing repair shops and technicians. These are not just tools anymore; they are transforming how technicians approach diagnostics and repair, ultimately enhancing service delivery and customer satisfaction.

Skill set evolution

Diagnostic tools are driving a shift towards specialized skill sets among technicians. With advancements like AI and IoT, technicians are increasingly required to be proficient in handling complex hybrid and electric vehicle systems, ADAS, and advanced diagnostics.

Operational efficiency

Modern diagnostic tools streamline operations within repair shops by reducing diagnostic times and enhancing accuracy. This efficiency translates into quicker turnaround times for repairs, minimizing vehicle downtime and optimizing service center productivity.

Customer expectations

Customers now expect quicker diagnoses and more accurate repairs facilitated by advanced diagnostic tools. Repair shops with these technologies can meet and exceed these expectations, enhancing customer satisfaction and loyalty.

Looking ahead

The future of diagnostic tools in the automotive industry holds promising advancements that will continue to redefine how vehicles are diagnosed and repaired. Innovations in AI, IoT, and AR are poised to further revolutionize diagnostic tools’ capabilities, offering new opportunities and challenges for technicians and repair shops.

Integration of AI and machine learning

AI will play an increasingly pivotal role in diagnostics, leveraging data analytics to predict and preemptively address vehicle issues before they escalate. This proactive approach will not only improve vehicle reliability but also reduce owners’ maintenance costs.

Expansion of IoT connectivity

IoT devices will continue to expand their role in diagnostics by providing real-time data from vehicles to technicians and service centers. This connectivity will enhance remote diagnostics capabilities and enable predictive maintenance strategies, further optimizing vehicle performance.

Advancements in augmented reality (AR)

AR technologies will enhance visualization capabilities during diagnostics, allowing technicians to overlay digital information onto physical vehicle components. This immersive experience will enable more precise diagnostics and facilitate complex repairs with greater efficiency.

Conclusion

In conclusion, the future of diagnostic tools in the automotive industry is bright and dynamic. By embracing these advancements and continually updating their skills, auto technicians can position themselves at the forefront of vehicle diagnostics, offering superior service and expertise to their customers.