Electric vehicles (EVs) are on their way. Depending on where you live, the number of EVs on the roads may vary. But make no mistake, the transition to EVs is gaining momentum and will continue to do so over the next five to ten years—and beyond.

An increased awareness of the benefits of EVs is propelling governments and manufacturers to accelerate their plans to convert the world’s vehicle fleet from internal combustion engine (ICE) power to that provided by electric motors connected to batteries. Some auto industry manufacturers have announced that they will stop making ICE vehicles after a specific date. Additionally, some governments have also indicated their plans to ban ICE vehicle sales after a certain point in time.

Schedule a free demo today!

Boost your shop sales

Simplify shop management

Empower your technicians

What does this mean for the average independent auto repair shop that makes its living servicing ICE vehicles on a daily basis? Let’s take a deeper look at some aspects of this coming change in propulsion systems and how to prepare your shop for it.

What’s the current state of electrification in the auto industry?

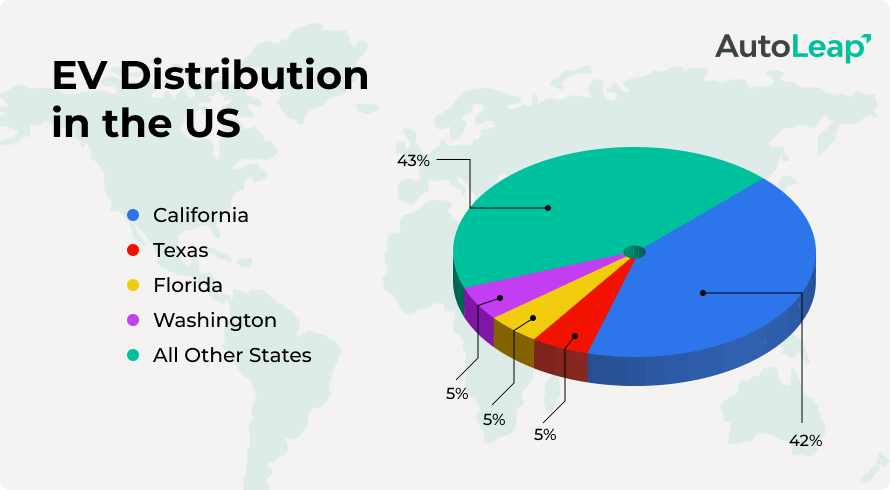

While sales of new EVs are currently less than 4% of all vehicles sold in North America, some places have more than others. The chart below shows the distribution of registered EVs in the US based on findings from the US Department of Energy:

This data shows that California is home to the most EVs, followed by Florida, Texas, and Washington. These four states have 585,900 of the 1,019,260 EVs registered in the US (or 57%), leaving the remaining 46 states with 433,360 registered EVs shared between them. Four states have less than 1,000 EVs apiece (Alaska, Montana, Mississippi, and West Virginia), while North Dakota, South Dakota, and Wyoming have less than 500 each.

What’s the bottom line? EVs are here to stay, and with time, their numbers will increase. This is backed by a study revealing that rising electricity costs had no impact on EV adoption for households, meaning that it shouldn’t be a concern for vehicle manufacturers in the future. Moving forward, it’s important that your shop’s EV expertise keeps up with vehicle purchasing habits in the area—if people are buying EVs, there’s no reason why you shouldn’t learn to work on them. In the meantime, most vehicles on the roads will continue to be powered by internal combustion.

However, there are a good number of EVs running around in areas that have a well-built infrastructure for these vehicles dating back as far as 2010, when last generation Nissan Leafs, Chevy Bolts, VW e-Golfs, and Tesla Roadster, Model S, and Model X vehicles were new. Why not start with these as potential EVs for your shop to work on? After all, EVs have been on the market since 1997, when the General Motors EV1 provided a “glimpse of the future”—the future that’s now transpiring.

Has electrification impacted independent auto repair shops?

Not a whole lot yet, but it’s time to get prepared. At the moment, the vast majority of vehicles that’ll come into your shop will continue being ICE-powered. Generally speaking, these vehicles will be on the roads for longer periods of time due to their popularity, meaning there will be more ICE business for you.

» Want more shop strategies to prepare for EVs? Click here to read our eBook.

Don’t ignore the hybrids

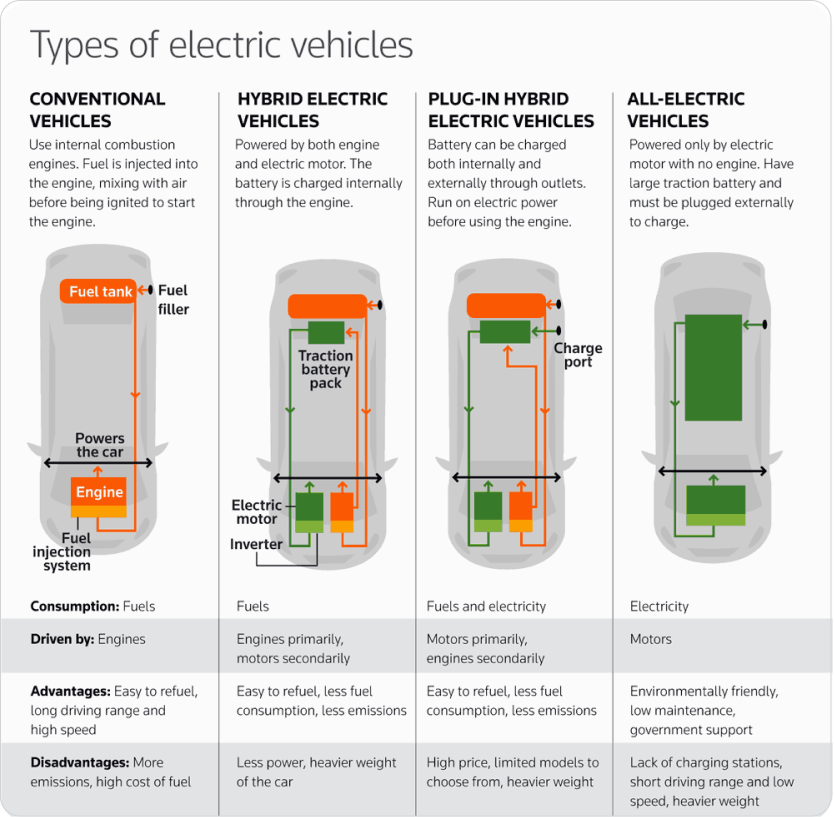

Mixed in with those ICE vehicles are likely to be a certain number of hybrid vehicles. The popularity of the Toyota Prius and other vehicles of this type means that it’s important knowing how to work on them. How’s this important for EVs? Well, hybrids have two drive systems: ICE and battery electric. Being able to work on hybrid vehicles means that your shop understands these EV-related items:

· Battery packs

· High-voltage electrical systems

· Electric motors

· Regenerative braking systems

· Software updates

Knowing the types of EVs and how to work on them is important. The US Department of Energy has showcased some configurations of EVs currently on the market:

According to a recent study by IMR Inc., 75% of the 1,000 US independent auto repair shops surveyed indicated that some part of their business was from servicing hybrid vehicles. The actual percentage ranged from 4.2% to 7.7%, with the Northeast and Western US regions reporting the highest percentages. In addition, 87% of these shops have seen an increase in the number of hybrids coming in for service over the past two years. All good reasons to know how to work on hybrid vehicles!

Unfortunately, the same study noted that only 30% of these shops had invested in any hybrid or EV training for their techs, and only 27% had invested in tools or equipment for these vehicles. Ironically, more than 75% of these shops believe that EVs and hybrid vehicles will have an impact on their business over the next five to ten years. Where does your shop stand on this issue?

What is the expected proliferation of electrification?

Within the next few years, there will be a much broader selection of EVs available from both the legacy vehicle manufacturers and a host of new startups. In addition, the size and density of the EV charging network should expand significantly with time. As we approach 2030, the cost of batteries is expected to come down to the point where an EV can be purchased for the same price as an equivalent ICE vehicle.

While EVs continue gaining traction, ICE vehicles will face ever more stringent emissions regulations, making them more expensive. So when the average new car buyer can purchase an EV at an affordable price, and the charging landscape is much more widespread and convenient, there should be few reasons left to purchase an internal combustion engine vehicle over an EV. That is when sales will take off and surpass those of ICE vehicles. It’s a good idea to prepare your shop for that day!

How will auto repair shops be impacted in the near term and over the next 5 to 10 years?

For most independent auto shops located outside of California’s major metropolitan areas, there is some time to adapt. The key is to watch the growth curve in your area so that you can be prepared when the time is right. And should a technological breakthrough come to pass that allows EVs to be affordable and fully charge their batteries in the same time it takes to fill an ICE vehicle’s gas tank, it’s time to jump in with both feet!

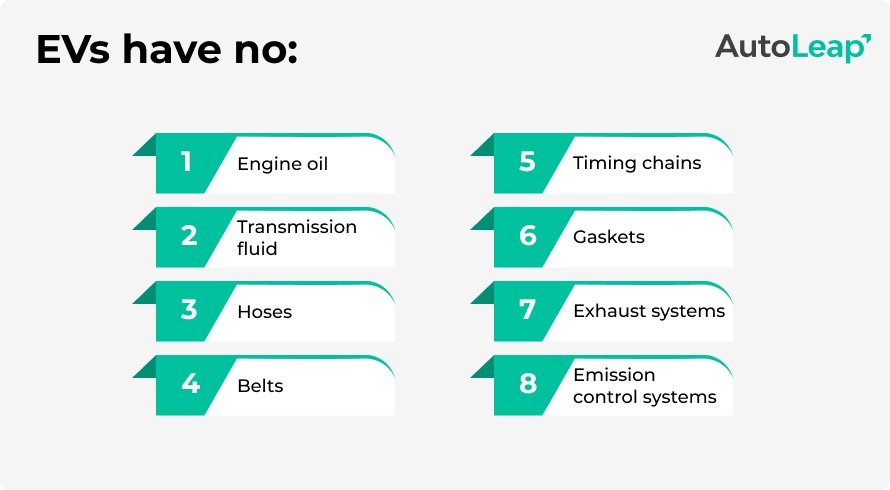

Be prepared: EVs need less regular maintenance

In the meantime, as the numbers of EVs on our roads increase (and their warranties end), there will be an increasing need for independent shops that can expertly work on them. However, this will reveal another cold, hard reality: EVs are much simpler machines that require much less maintenance.

And thanks to regenerative braking systems, an EV will rarely need its brake pads replaced, which means you lose out on the added parts margin.

There is an EV upside

But it’s not all doom and gloom for shops that commit to working on electric vehicles. Even though maintenance costs will be lower, some service and repair costs for EVs will likely be higher than ICE vehicles.

Why? The heavy battery packs powering EVs require heavier duty suspension components, which cost more to repair. Tires and shock absorbers are likely to have shorter lifespans and need more frequent replacement, thanks to heavier vehicle weights and the massive torque that electric motors produce from a standing start. Replacement electronic components will also be costly therefore allowing shops to charge higher margins. This is where much of the money will be made in an independent EV repair shop.

And let’s not forget about the many non-drivetrain parts of an EV that will still need service and repair work, just as they do on an ICE vehicle, including:

· Seat and window motor failures

· Electric charging door failures

· Climate control issues

· Faulty switches

· Infotainment and display screen problems

How can auto repair shops prepare for electrification?

Here are some strategies you can adopt to make your auto shop ready for the EV revolution, whenever it arrives at your location:

Learn how to work on hybrid vehicles: There are enough of them running around to make the effort worthwhile. As mentioned above, getting some serious experience working with hybrids’ electric power systems will prepare your shop and your techs for full battery-electric vehicles.

Upgrade your auto technicians’ technology skills: High-level diagnosis skills are already needed for many ICE vehicle repairs. EVs will take this to the next level. Over-the-air software updates, battery troubleshooting, high-voltage safety protocols, advanced driver assistance systems, and complex infotainment systems will be required areas of proficiency for your shop and your techs. Adopting shop management software is also important. Your techs will need to learn the basics such as using scheduling tools for appointments and conducting digital vehicle inspections (DVI).

Acquire more advanced diagnostic equipment: The many electronic control systems in both internal combustion engine vehicles and EVs are best diagnosed using up-to-date computerized service equipment. You will need the latest hardware and software to fix the EVs that drive into your shop. Additionally, it’s important for shops to be equipped to deal with data in modern cars using Predictive Maintenance (PdM) features.

Hire the staff now that you will need in the near future: Sure, your current auto technicians should be upgrading their skills on a regular basis to keep up with today’s evolving and more complex vehicles. But also think about hiring people who have the specific skills to work on the electric vehicles that will be driving in any day now. Many of your local trade and technical schools are turning out graduates who know their way around electric and hybrid vehicle motors, batteries, and controllers. These fresh young techs grew up using computers, so electronic diagnosis is second nature to them.

Market your business properly: Shops that adopt EV maintenance first will have a first-mover advantage in the segment. Use social media marketing, create a website for your shop, and leverage word-of-mouth referrals to increase awareness about your services. To drive business further, you can get hybrid or electric cars with your shop’s name written on them to offer pick-and-drop services for customers coming into your store.

Streamline your shop’s operations with state-of-the-art software: Using modern automotive repair shop software is an excellent way to align your business with the latest tools. The best software available helps you sell more, save time, and empower techs with just a few clicks. Grow your business and delight your customers by providing excellent service all around to build credibility about your brand. Plus, when customers see you working on EVs with tablets and laptops in your workshop, they’ll know that your team is tech-savvy enough to work on their cars.

Conclusion

Now is the time to prepare for EVs, so you are ready when they arrive. No one knows for sure when EVs will gain mass adoption—however, the best course of action for the average independent auto repair shop is to build up its core competencies in the areas of knowledge that will be needed when EVs reach that tipping point. Becoming a shop that has deep expertise in working on hybrid vehicles is a good first step. Keeping an eye on EV sales figures in your area, as well as the numbers of EVs you see driving around, will give you a good sense of the speed of EV uptake where you are located. That way, you’ll be ready to say “Yes!” when you get that call asking, “Do you work on electric cars?”

Auto Repair Shop Management Software

AutoLeap is a powerful all-in-one auto repair shop software that helps to keep complete track of your business – from scheduling appointments to managing technicians and generating invoices.