It’s a world of emerging auto repair trends. With auto shop management software such as AutoLeap; helping shop owners automate their most time-consuming processes. But beyond technology, shops need to create other competitive edges. And optimizing the layout of your business is one potential differentiator.

Revamping your shop’s layout can help improve efficiency, prevent accidents, and improve your customer experience. Here are four automotive shop layout ideas for your auto repair business.

1. Manage space effectively

The size of your shop is just as important as how you use it. Dimensions of 23 x 60 feet are ideal for most small workshops, according to YouTuber and industry expert The Mechanic OC. Proper space allocation allows you to work on multiple cars in a relatively confined area. If you’re starting your design from scratch, it helps to plan just how much space you’ll need.

During this stage, remember to allocate space for:

- Parking cars and pulling cars out

- Organizing equipment and tools

- Storing spare parts

- Working on vehicles

- Accommodating customers (with a waiting area)

Keep equipment in the right place

Data Source: The Mechanic OC

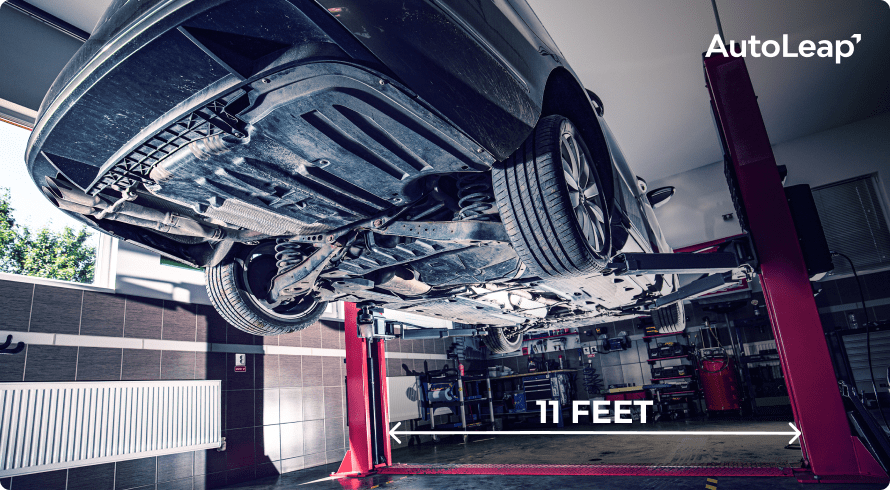

Your shop’s size determines what types of vehicles and machinery will fit inside. A two-post lift is necessary for any repair shop to conduct inspections and repairs. But how much space does a lift take up, and what’s the best way to position one?

You’ll need around 15 feet of horizontal space for a lift. Position one of the arms right up against a wall while placing the other around 11 feet away, as shown in the image above. The Mechanic OC says having this much room is ideal for any repair job. It’s also essential to leave around four feet empty next to the lift arm. This makes moving your toolbox around more accessible to work on the rear end of cars.

When you position your bays, leave space between them to prevent collisions between cars and make evacuating easy during emergencies.

Improve your shop’s aesthetics while increasing storage

Every building has an awkward space you can only use without compromising your shop’s look. However, you can store repair equipment by adding doors to these places. Similarly, a DIY hidden tool storage workbench provides quick access to equipment. This helps declutter and organize your shop while saving time during repair jobs since your technicians will save time looking for the right tools.

2. Professionalize the waiting room

First impressions matter while running a business. A clean and well-put-together waiting room can improve your customer experience. This means while customers wait for you to invoice their repairs, you make them feel comfortable at your shop by offering a neat ambience .

Here are some recommendations and examples of effective waiting room layouts:

- Minimize exposure to service bays: Keep the waiting area separate from the service bays to minimize customer noise and potential safety hazards. Maximizing the distance between these areas can enhance comfort and safety, allowing customers to relax without concerns about heavy machinery.

- Explore alternative solutions for smaller shops: In smaller shops where distancing may not be feasible, consider installing a protective glass panel between the waiting room and service bay. This provides a physical barrier while allowing customers to observe the repair process.

- Focus on cleanliness and accessibility: Design the waiting room for easy maintenance and accessibility. Ensure it’s kept clean and organized to create a welcoming environment for customers. Additionally, to accommodate the needs of all customers, consider factors such as seating capacity and accessibility for individuals with disabilities.

- Create opportunities for additional sales: Take advantage of the waiting room as an opportunity for additional sales. Research from JD Power reveals that 64% of mechanic shop employees wait while getting their cars fixed. Encourage upsell opportunities by adding a display shelf with your best consumer-grade products, such as car wax.

A quality waiting room can give shop owners the opportunity to offer additional services such as tire rotations, coolant top-offs, and wiper-blade replacements. Since you’re already working on their cars, customers are more likely to agree to these jobs, which could increase your shop’s average repair order size.

3. Make your shop a safe space

A well-designed auto shop layout keeps everyone in the building safe. A repair shop can carry various safety hazards—heavy equipment lying around, cars on lifts, chances of fires because of electrical and mechanical vehicle faults, and countless other potential threats.

Bearing this in mind, here are a few ways to organize your shop layout for excellent safety:

- Take precautions against fires: Fires can arise when working with flammable substances, so place these as far away from sparks and heat sources, such as electrical outlets and heavy machinery. Additionally, your shop should have ample well-maintained B fire extinguishers to comply with the Occupational Safety and Health Administration’s (OSHA) requirements.

- Keep safety equipment close: To reduce accidents, it’s a good idea to designate spots for protective equipment near where technicians work. Place hangers near service bays where techs can store their overalls, gloves, and protective goggles.

- Factor in an evacuation route: OSHA requires all workplaces to have at least two unobstructed fire exits. Additionally, it would help if you had an evacuation plan that your customers and employees are aware of.

- Install sufficient lighting: With proper lighting, your store will look good and have fewer hazards. Customers are less likely to trip over objects, and employees are less likely to make costly mistakes, leading to a better overall process.

- Reduce hazards: It’s essential to restrict customer access to areas with heavy machinery and ensure that every employee handling such equipment uses the appropriate protective equipment. Doing so can help reduce auto repair business insurance liability and worker’s compensation payouts.

4. Positioning and equipping your bays for maximum productivity

Toyota’s Express Maintenance program is one of the best models for repair shops to adopt. This program entails parking vehicles close to the service bay to reduce driving time. It also uses a “pit crew” approach—technicians work on each car to inspect and service parts. Each tech is assigned a specific job, so while some work under the hood, the rest inspect the wheels and brakes.

Here’s what also happens with Toyota’s Express Maintenance:

- Oil and filter changes, along with other fluids

- Tire inspections and rotations

- Vehicle inspections

Your techs can address areas of concern during a repair since the required tools are placed on three sides of the service bay. These bays are placed close to save time since industry experts recommend that each technician cover 1.5 of them. Similarly, positioning toolboxes and spare parts close by can help reduce the time each car spends idle on a bay while techs look for appropriate tools.

Closing thoughts

You worked hard optimizing your auto repair shop layout to be more efficient and safe while improving its look and feel. Now, it’s time to see the results come in.

After revamping your shop’s floor plan, invest in modern auto repair shop software to help you sell more, save time, and empower techs while providing real-time insights to track your shop’s health.