Are you looking into 2-post car lifts? But you are worried about how to install one in 30*40 ft garage.

Before you jump into arranging and installing permanent fixtures, take your time to plan the shop layout. Look in detail into bay depths, ceiling requirements and safety compliance.

Read our guide on 2-post lift layout requirements and learn how to improve efficiency and reduce risks.

Understanding 2-post car lift basics

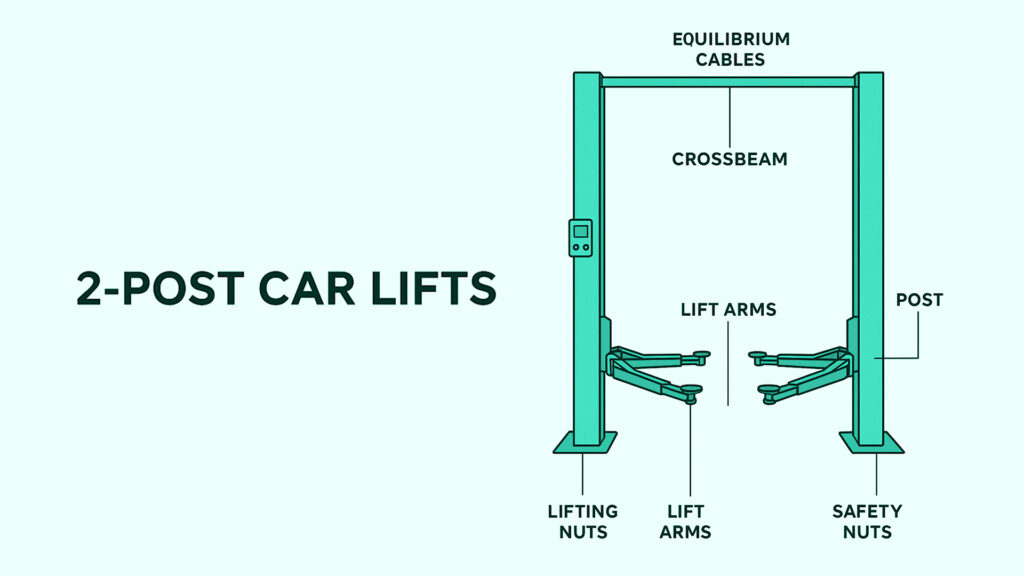

2-Post car lifts are made of large steel structures. It can be two folded or rolled steel columns or two posts with arms on each. These arms are used to raise cars to check wheels, sides, or under the vehicles. A motor is attached to each post that turns screws inside. There are two types of screws: lifting and safety nuts. The former supports the arms of the 2-post lift, and the latter supports a smooth lifting process.

The 2-post lift is connected to a set of cables or chains known as equilibrium cables. They run above or below the posts to ensure synchronization. This is important for 2-post lifting screws to raise and lower at the same rate. This way, any car lifted remains stable regardless of the weight difference on the two sides of the vehicle.

Symmetric vs. asymmetric lifts: Which works best in a 30×40 garage?

There are two types of 2-post car lifts:

- Symmetrical 2-post car lifts have equal arm lengths. The vehicle is in the middle, the same distance from each arm on each side, and the weight is uniformly spread across the two lifting arms.

- Asymmetrical 2-post car lifts have one arm on each side that is a little longer than the other. This lets you move the car a little further back on the lift, which means that most of the weight of the car is on the rear arm on each side of the lift.

The load capability of 2-post lifts is an important element to consider in the process of designing and laying out a 30*40 automotive garage. Common capacities are 7,000 to 18,000 pounds or so, and the lift you choose will depend on what kind of vehicles you’ll be servicing, such as passenger cars or light-and medium-duty trucks.

Lifts with more capacity may be much bigger than you need to get an adequate lift. They take more space on your shop floor compared to the bay configuration just because of ceiling height. By accommodating lift capacity with a 30*40 shop’s footprint, already tight space is used to maintain safe operation systems and optimize workflow efficiency.

2-Post car lift ceiling height requirements

Different 2-post lifts come with different heights. It is important to measure your shop’s ceiling height and choose a 2-post lift within the height requirements. Most lifts require a minimum of 10-12 feet of ceiling height. At this height, the post can fully raise the vehicle without hitting the lights or ceiling joists.

Coats Company’s 10K 2N1 lift, for example, requires a minimum ceiling height of at least 12 feet 6 inches. These measurements depend on the setting you place it at. This stretch has an overall height of 148 inches.

When you get into the larger capacity lifts (16K, 20K 2-Post), your required ceiling height is then going to be at least 17 feet. These models are 199.5 inches high and tailored for heavier vehicles that need additional vertical clearance.

Here are some tips to follow:

1. Still calculating the ceiling height required? Follow this formula: lift height + vehicle height + buffer (~7″)

2. Some common ceiling heights for 30*40 shop layout:

Vehicle Type | Vehicle Height Range | Ceiling Height |

Compact and Small Cars | 4.5–5.2ft | 10-11 ft |

Sedans | 4.5–5 ft | 12 ft |

SUVs and light-duty trucks | 5.2– 6.2 ft | 12 ft |

Trucks, Large vans or medium-duty trucks | 6– 6.5 ft | 14-16 ft |

3. As automotive owners plan for purchasing a 2-post lift, they should plan for an additional clearance height of 14-16 feet. This can accommodate larger vehicles comfortably.

Optimal bay depth and layout tips

Both the width and depth are also vital in ensuring/separating safety and efficiency when it comes to designing a 2-post lift bay layout. Typically, a clear door swing, technician access, and pick-up placer clearance for a 2-post lift will demand an absolute minimum bay size of 12’ wide.

For depth, 20 to 24 feet is fine for most passenger cars, SUVs, or light trucks. It offers enough clearance so you’re less likely to bang your door on a cabinet when you get out of the car. Also, not too little room that you feel overwhelmed every time you try to pull in or back out.

In a 30×40 shop, you have the space to set up more than one lift bay without compromising on circulation lanes and storage areas. Thus enabling the workplace floor to deliver productivity along with safety. If you are designing 30*40 auto shop, here are some layout tips to accommodate 2-post lifts:

- Try a demo and park a vehicle in the shop. Use informal markers to mark the lift posts area.

- Specific garage door openers can help minimize interference between the lift posts and door.

- Think of a plan where you accommodate as many vehicles as possible. This is a head start on how much space you require.

- Always follow a contingency plan. Scaling your autoshop business means more 2-post lifts. Having additional garage or pedestrian doors can help optimize space.

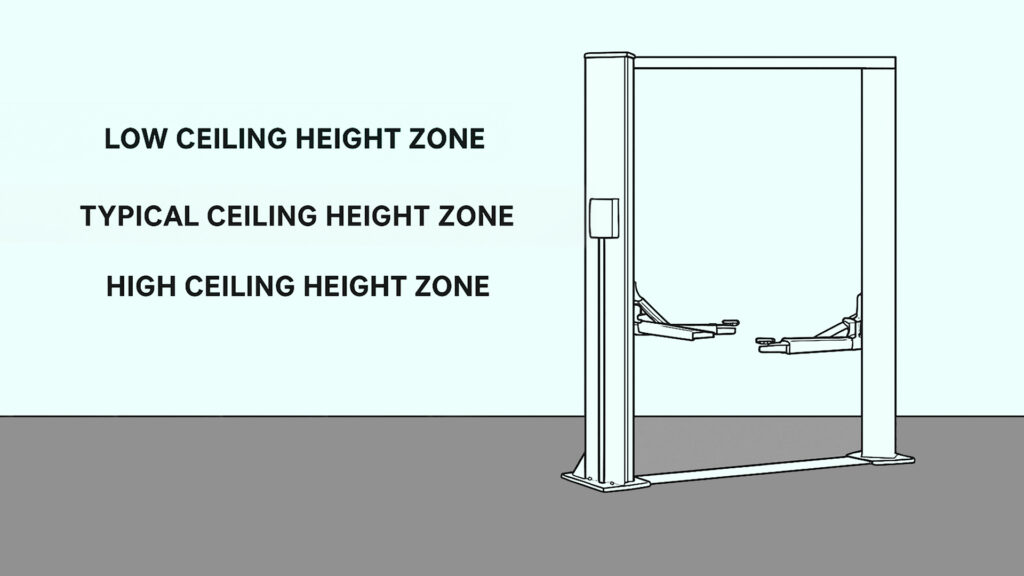

In the image above:

Low Ceiling Height Zone (top red band): This represents the ceilings in which a 2-post lift cannot effectively work. Some may not work safely, as the vehicles are likely to strike the ceiling.

Standard Ceiling Height Zone (middle gray band): This is the standard height at which the majority of two-post lifts will operate as designed. It lifts most passenger cars high enough for undercar service without scraping the ceiling.

High Ceilings Zone (beige area above the lift structure): This means higher pantry heights which can also give you much more headroom. Perfect for Lifting larger vehicles such as SUVs, Vans, and Trucks to full height.

Critical floor requirements and preparation

A concrete slab with standard requirements is a must for 2-post lift installation. This is to support installation and provide stability under pressure load. The minimum concrete thickness should be atleast four and a half inches. Double-check the thickness requirement based on lift model, configuration and capacity you choose for your autoshop.

The concrete is also checked for its strength and anchor embedment. The concrete should have a compression strength of at least 3,000 PSI. This is to handle the weight and operation of the lift safely. The minimum anchor embedment in the concrete should be 3-1/4 inches for anchor bolts ¾ x 5 ½ inches.

Undersized or weak, rough, sloped surfaces make it difficult to level properly. Spalling and cracks reduce anchor points and water damage can lead to loss of integrity in concrete. In addition, a buried rebar system in a floor can complicate and limit drilling for anchor bolts.

Such problems can often be prevented with site preparation for the successful installation of a 2-post car lift:

- Gravel Layer: gravel layer is laid under the concrete slab. This prevents concrete from settling and cracking.

- Reinforcement: Include reinforcement materials such as rebar or wire mesh within the concrete slab. It helps distribute the load and avoid cracking.

- Curing Time: Allow the concrete to cure adequately before installing the lift. A new concrete slab should cure for at least 28 days.

Electrical and utility requirements

A 2-post car lift operates safely with proper electrical requirements. Incorrect power setups can damage the motor, cables, or vehicles. This can lead to expensive repairs and equipment breakdown.

Small garages or 30*40 ft auto shops choosing single-phase lifts require a 220V power supply. This voltage is compatible with small commercial garages. Heavy-duty lifts require a 220-440V supply. It’s highly efficient for use in industrial garages.

Before installation, plan the power route to the power unit. This helps conduit and cable avoid moving parts. Properly ground the motor to avoid snags or abrasion. It is important to connect the green ground to a verified ground. Ensure wirings are away from car doors, locks, and cables. Label the breaker for quick tagout and also have a local disconnect within line of sight.

OSHA requires auto shop owners to use ANSI/ALI ALCTV-certified lifts, which meet the electrical safety requirements. They must also ensure lifts are properly grounded and maintain minimum approach distances from live electrical parts.

Safety zones and operational clearances

2-post car lifts should be installed safely. This requires garage space for the equipment and also operational clearance around the vehicle. Ample space on each side is a must to open vehicle doors and move parts around. Overhead clearance is the space that considers lift’s height and the tallest vehicle your shop services.

The placement of your 2-post car lift leaves minimum of 600mm between and other objects. This is important for emergency entrances and exits. Also, the space between helps smooth operation when the vehicle is lifted.

Consider how vehicles will arrive to and leave the lift area. An ideal location for installation would be the area where vehicles can freely move in and out without any obstacles. This is a feature that improves efficiency and with safety in mind, means no more potential accidents or damage.

Understanding building codes for automotive lifts

Did you know 15,000 workers got hurt from unsafe lifts? It happened due to no safety locks, ill-trained workers, and irregular safety records. This is why it is important to adhere to safety codes and compliance requirements.

Auto shop owners perform regular checks to ensure all requirements are met. Here is a list of important compliance to check:

- The Health and Safety Executive (HSE) and others say it’s key to have working arm locks.

- In case a car falls off the lift. This was due to bad adaptors. To avoid such dangers, ANSI/ALI standards ask to always show the weight limit.

- Use certified adapters. It can help know how much weight a lift can handle and safely perform car services.

- Get a label of approval from the Automotive Lift Institute (ALI). This is proof your auto shop follows all safety standards related to 2-post car lifts.

- All lifts must follow OSHA rules and local laws/regulations for setup, usage, and safety features.

- Permit requirements vary as per local municipality laws. You need to check local regulations for installations and the inspection process. It is always a good idea to contact your local municipality and ask about specific permits before installing car lifts.

- Get insured for your car lift. Commercial general liability insurance covers injuries to third parties that occured due to car lift. Equipment insurance covers physical damage from theft, or failure to the lifts. Also, get lift warranty at the time of purchase to reduce overall risk exposure.

- Ensure the lift is regularly maintained according to the manufacturer’s manual. Failure to do so can void warranties and increase liability.

- Contact certified engineers for the installation of lifts.

Safety checklist to follow when using 2-post car lifts

- Regular training for lift operators for smooth operations

- Read and follow manufacturer guidelines

- Make sure the area around the lift is clean without obstructions.

- Use protective gear like foam door guards and head bumpers.

- Check vehicle weight before lifting.

- Lower the vehicle onto the safety locks.

- Make sure each arm is not overweight. Balance the vehicle in a way that no arm carries more than ¼ of the total weight.

- No items must be placed under the lift’s load.

- Keep all lift parts lubricated.

- Schedule annual inspections to cover issues not shown during day-to-day checks.

Optimizing your shop layout for maximum efficiency

Start with using certified 2-post lift designs that accommodate your specific space. This includes limited floor area in a small garage, to servicing a fleet of vehicles in a large shop. By strategically placing lifts and planning ahead for additional equipment such as tire machines and alignment racks, you ensure that your 30* 40 shop layout remains flexible and scalable as your business grows.

And just as important is the creation of work patterns. It enables smooth flow of vehicles and logical work order sequence to reduce pinched locations and wasted travel. As a result, increasing productivity and customer satisfaction.

Real-world installation challenges and solutions

Old and existing buildings have restricted space and design. This is why it is difficult to install heavy car lifts or other machinery. Retrofitting repairs and modifies existing buildings for longevity.

MEP engineers are now redesigning older buildings while implementing new technologies. MEP engineering services with advanced automation tools are an integral part in overcoming these challenges and verifying that the upgrades meet functional requirements.

Implementing retrofitting solutions is expensive. Replacing old equipment with new ones is more costly. Conduct a thorough cost-benefit analysis and ensure retrofitting gives significant returns in terms of operational efficiency and energy savings. Investigate financial incentives, opportunities and rebates for retrofits to support the reduction of upfront costs and enhance project viability.

Conclusion

Creating a safe and efficient 30×40 shop 2-post lift layout ensures the safety, compliance, and long-term efficiency of your automotive business. All depends on having the right plan for your 30 x 40 building. From the height of ceilings and bay sizes, all the way to flooring, electrical and clear floor space area.

Every little detail matters when it comes to setting up your lift. And as soon as your shop is maximized for space and workflow, the next step is managing it effectively. This is where AutoLeap comes in. AutoLeap helps you manage operations, keep on top of jobs, schedule appointments, and maximize your shop’s investment. A well-planned layout and the right software will help you run a safer, smoother, and more profitable shop.

FAQs

How far apart is a two-post lift?

Typically 10–12 feet between posts, depending on model and vehicle size.

What are the dimensions of a 2-post car lift?

Most lifts are around 11–12 feet tall, with a bay width requirement of 12–14 feet.

How much clearance is needed for a car lift?

A minimum of 12 feet ceiling height; 14–16 feet is recommended for larger vehicles.

Can you put a car lift in a 10-foot garage?

Generally, no, since most 2-post lifts require at least 12 feet of clearance.