You expect efficiency from your team inside the shop. The right air compressor can help in this area, boosting your mechanics’ productivity.

In this blog post, we’ll discuss the best air compressor options for your auto repair business. Let’s dive in!

Schedule a free demo today!

Boost your shop sales

Simplify shop management

Empower your technicians

So, how does an air compressor even work?

Air Compressors Direct defines an air compressor’s functionality as “continuously sucking in surrounding air and mechanically squeezing it through internally-moving components and into a usable force for powering air tools. Once the maximum air pressure is reached (PSI), the duty cycle is complete.”

Compressor Services notes that while it may vary, five square cubic feet per minute (SCFM) is a benchmark to consider standard air compressor usage by many mechanics in auto repair shops.

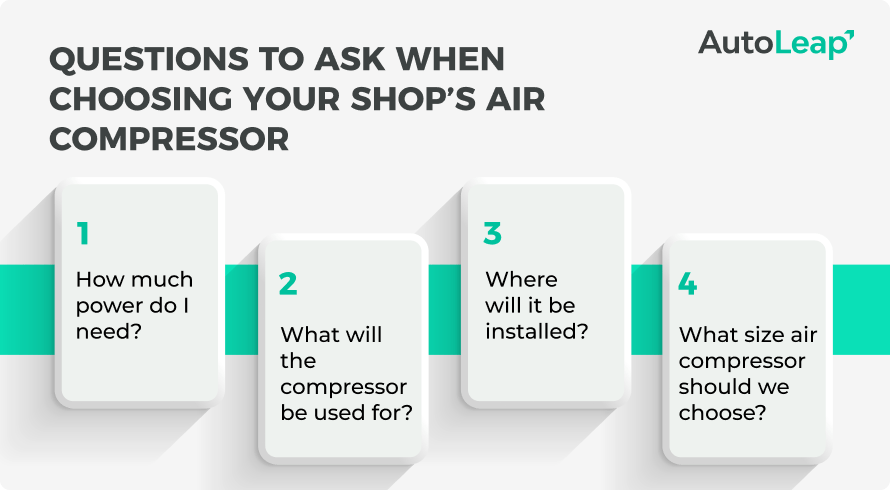

Ask yourself the following to determine the type of air compressor usage your shop will need:

- How often will our mechanics use the air compressor?

- What specific tasks around the service bays will they use it for?

- How long will it take to complete these responsibilities?

Sit down and evaluate these considerations in detail. We’ll cover more on that later to help with this process!

How do I choose an air compressor for my auto repair shop?

Power needs

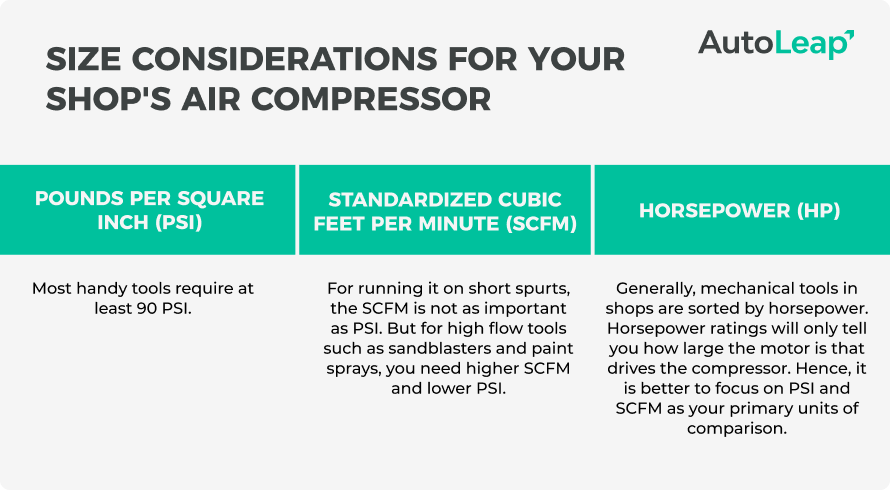

An air compressor delivers 4 to 5 SCFM at 100 PSI for every horsepower unit, according to the Air Compressor Guide.

Use this benchmark to evaluate the exact SCFM your shop will require.

Energy usage

Professional-grade air compressors for auto repair shops are designed to withstand heavy usage for many responsibilities around the service bays, as they are durable and portable.

However, there are other considerations with this usage. One primary concern is the amount of energy they use to operate! As a growing shop focused on long-term profitability, the last thing you want is an out-of-control electric bill.

Take the time to calculate your usage needs and project how this will affect your electrical usage in the shop. Then, discuss these usage limitations with your team and stick to the plan.

These two components must factor into which air compressor you choose for your shop.

What will the air compressor be used for?

As we discussed, ensure you have a list of all your potential usage needs for the air compressor and how often you will execute these tasks.

That consideration will influence what air compressor features and specifications matter the most.

Other factors influencing your decision are how quiet you want it to run or how clean you want the air to be. The placement of your air compressor is another discussion point. It’s not just about filling a space; it’s about integrating this vital instrument into your shop.

Here are some other primary factors to consider:

- Proximity to power sources: Your compressor’s location should be conveniently near power sources. Seems obvious, right? But a thoughtful plan here makes a difference. It will help ensure seamless operation and reduce the need for extensive wiring.

- Ventilation: Good ventilation is not a luxury; it’s a necessity. An adequately ventilated space prevents overheating, ensuring your air compressor runs efficiently.

- Business flow: Keep the rhythm uninterrupted. Think about how the compressor’s location will interact with other areas of your business. The goal is to enhance workflow, not hinder it.

- Electrical compatibility: Ensure your building can support the compressor’s electrical requirements. It’s about balancing the compressor’s needs and your facility’s capabilities. And you want to remember the added costs associated here as well.

Beyond the basics, additional factors contribute to your workplace’s efficiency and safety. Some additional shop considerations for a new air compressor include:

- Noise level: Air compressors can be pretty loud, so consider the noise impact on your work environment. Placing it where noise is less disruptive to employees and customers is ideal. If noise is a significant concern, consider soundproofing options or enclosures designed for compressors.

- Safety and accessibility: Ensure the air compressor is easily accessible for maintenance and inspections but also situated in a way that doesn’t pose a hazard to staff or customers. Adequate space around the compressor for safe operation and maintenance is crucial.

- Moisture control: If your service bays are prone to humidity, it’s essential to consider how moisture in the air can affect the compressor. Placing it in a dry area or using a dehumidifier can help prevent moisture-related issues.

- Space for expansion: Consider your shop layout and how you allocate space for additional service bays or equipment. Ensure there’s room to upgrade or add more air compressors in the future, much like planning for additional workstations.

- Room temperature: Excess heat from an air compressor can raise the temperature in your shop to an uncomfortable level. You’ll need to remain mindful of this detail and the potential disruptions it may cause. The comfort of your techs matters, especially as they keep pace with a rigorous workload.

What size air compressor do I need for my mechanic shop?

Depending on your needs, air compressors come in all shapes and sizes. Options include everything from 12-volt units to large industrial systems like rotary pumps.

To choose the right size for your shop, you need to focus on:

Once you consider these details, you can determine the size you need. Most tools have specifications and air compressors that match. You will need a rating of about 90 PSI and around 4 SCFM for impact wrenches or ratchets – the two most used air tools.

Best air compressors for your auto repair business

1. Ingersoll Rand Type-30 (reciprocating air compressor

The Ingersoll Rand Type-30 is a reliable and durable reciprocating compressor, well-suited for heavy-duty auto repair tasks for your typical auto repair shop. It comes with a range of models, varying by CFM and PSI ratings to meet your different service needs.

Pros:

- Reliable

- Durable

- Easy maintenance

Cons:

- Noisy

- Less energy efficient

Cost:

- Smaller models with lower capacity and horsepower (e.g., 5 HP) can range from $1,500 to $3,000

- Mid-range models with moderate capacity and horsepower (e.g., 10 HP) can range from $3,000 to $6,000

- Larger models with higher capacity and horsepower (e.g., 20 HP or more) can range from $6,000 to $15,000 or more

2. Quincy QT-54 Pro Series (reciprocating air compressor)

Known for its quality performance and longevity, the Quincy QT-54 is another excellent choice for auto repair shop’s compressed air systems. It’s designed for continuous operation and can handle various air tools effectively.

Pros:

- Reliable

- Powerful performance

- User-friendly per reviews

Cons:

- Expensive depending on budget

- Not very portable

- Requires regular maintenance

Cost:

The cost of the Quincy QT-54 Pro Series reciprocating air compressor can vary from $1,899 to $5,599 (as of this writing) depending on the size and your shop’s capacity needs.

3. Atlas Copco GA 11 (rotary screw air compressor)

The Atlas Copco GA 11 is a powerful and energy-efficient rotary screw compressor equipment that’s suitable for larger automotive shops with extensive demands. It delivers consistent performance and minimizes energy consumption.

Pros:

- Energy efficient

- Quiet to operate

- Compact design

Cons:

- Less affordable for small shops

- Not suitable for limited use

- Requires specialized maintenance

Cost:

The cost of the Atlas Copco GA 11 Rotary Screw Air Compressor is on the higher side, with a wide range depending on the specific model from $10,000 to $300,000 (as of this writing).

4. California Air Tools 10020C (Ultra quiet oil-free air compressor)

If low noise levels are essential in your auto repair shop, consider the California Air Tools 10020C. It’s a portable and quiet option, making it suitable for smaller auto repair businesses in noise-sensitive areas.

Pros:

- Reliable performance

- Ultra-quiet operation

- Affordable price tag

Cons:

- Limited power

- Long recovery time

- Less durable

Cost:

The California Air Tools 10020C ultra quiet oil-free air compressor will cost you around $450.

5. Sullair ShopTek ST4 (Oil-lubricated rotary screw air compressor)

The Sullair ShopTek ST4 is a robust, oil-lubricated rotary screw compressor. This option delivers excellent performance and reliability. It’s suitable for medium-sized auto repair shops that require a constant supply of compressed air.

Pros:

- Versatile use

- Reliable performance

- User-friendly controls

Cons:

- Space requirements

- Expensive price tag

- For specialized services

Cost:

Click here to review models, specs, and pricing details for the Sullair ShopTek ST4 oil-lubricated rotary screw air compressor.

6. Campbell Hausfeld DC080500 (quiet air compressor)

The Campbell Hausfeld DC080500 is a budget-friendly and quiet compressor, making it suitable for light to medium-duty tasks in smaller auto repair shops.

Pros:

- Reduced noise

- Compact and portable

- User-friendly controls

Cons:

- Limited Power

- Low tank capacity

- Limited accessories included

Cost:

Thanks to its small size and low tank capacity, the Campbell Hausfeld DC080500 quiet air compressor is quite affordable. It costs around $300.

7. Rolair VT25BIG (oil-lubricated compressor)

The Rolair VT25BIG is a portable, durable compressor for on-the-go auto repair shop needs. This air compressor can easily handle various pneumatic tools in your shop.

Pros:

- Low noise operation

- Durable design

- Quick recovery time

Cons:

- More expensive end

- Not suitable for oil-sensitive services

- Regular maintenance requirements

Cost:

The Rolair VT25BIG oil-lubricated compressor will cost you around $500.

8. Powermate VX PLA4708065 (electric air compressor)

The Powermate VX PLA4708065 is a versatile and high-capacity air compressor that meets the wide-ranging service demands of busy auto repair shops.

Pros:

- Powerful motor

- Durable design

- Large tank capacity

Cons:

- Noisy

- Oil carryover in air

- Regular maintenance requirements

Cost:

The Powermate VX PLA4708065 electric air compressor will cost you upwards of $2,000.

9. BelAire 318VL4 (Two-stage air compressor)

For heavy-duty applications, the BelAire 318VL4 is a two-stage air compressor with high pressure and excellent air delivery. This model is perfect for demanding services in an auto repair shop.

Pros:

- Powerful performance

- Durable build

- Large tank capacity

Cons:

- Expensive for smaller shops

- Not suitable for oil-sensitive operations

- Regular maintenance requirements

Cost:

BelAire 318VL4 is a heavy-duty air compressor with a price range from $2,200 to $2,600.

10. KAESER Series (Rotary screw air compressor)

The KAESER industrial air compressor series is highly regarded for its efficiency and reliability. These rotary screw air compressors are more suitable for larger auto repair shops with heavy-duty air requirements.

Pros:

- Efficient performance

- Reliable, durable design

- User-friendly controls

Cons:

- Expensive options

- Limited portability

- Specialized maintenance needs

Cost:

Prices from this air compressor series range widely depending on your horsepower requirements, starting at $8,000.

Different types of air compressors

Since an auto repair shop needs to power different pneumatic tools, inflate tires and use a spray gun for spray painting, reliable air compressors quickly become a must-have!

Let’s break down the different types of air compressors and review their functionality:

- Reciprocating/piston air compressors: Reciprocating air compressors, often known as piston compressors, operate similarly to piston-driven pumps. Due to their adaptability and cost, they are among the most popular compressors used in auto repair shops.

- Rotary screw air compressors: Two interlocking helical screws are used in rotary screw compressors for compressed air. They provide a constant flow of compressed air and reviewers find them very effective. Auto repair shops frequently use this compressor due to their dependable performance and high air demand. They are perfect for larger shops where a constant air supply is essential.

- Scroll air compressors: This compressor uses two spiral elements for compressed air. They are appropriate for smaller shops offering specialized services because they are compact, quiet, and low maintenance. Scroll compressors are used with small pneumatic tools and airbrushing.

- Centrifugal air compressors: Centrifugal air compressors are used in bigger auto assembly factories and heavy-duty auto repair shops where high-volume, high-pressure air is needed. These effective compressors function by compressing air using the centrifugal force theory. Unfortunately, they are difficult to maintain and aren’t the most practical option for smaller auto repair shops.

- Oil-lubricated compressors: Compressors with oil lubrication are more dependable and appropriate for heavy-duty auto repair activities. That’s because their lubrication slows the wear on working parts. They do, however, need routine maintenance and frequent oil changes.

- Portable vs. stationary air compressors: You can select between a portable air compressor and a stationary air compressor depending on the size of your shop and its mobility requirements.

Portable compressors are appropriate for smaller auto repair businesses or shops with limited space since they are compact, lightweight, and portable. On the other hand, stationary compressors are bigger, have a higher capacity, and stay fixed in one place.

More air compressor considerations

- Tank size: The volume of compressed air that an air compressor can store depends on the tank size. Larger tanks offer a more consistent air supply, requiring less continuous use of the compressor. A larger tank is advantageous for auto repair shops because it ensures a constant airflow for diverse activities without excessively cycling the compressor.

- CFM (Cubic feet per minute) and PSI (Pounds per square inch): When selecting an air compressor for your auto repair shop, CFM and PSI are specifications to keep in mind. While PSI monitors the air pressure level, CFM shows how much air the compressor can produce. Depending on the tools and equipment you use in your auto repair business, different CFM and PSI requirements will apply.

Advantages of air compressors

With their steady supply of compressed air, air compressors deliver plenty of value for auto repairs and general maintenance work on vehicles.

Let’s break down some of the ways you can maximize a quality air compressor in your shop:

- High-pressure dusting & washing: Air compressors simplify cleaning dirt and dust behind an engine block or other parts of a vehicle where access is difficult.

Its nozzle end has enough force to blow away settled dirt or soot without additional wiping or scrubbing. Choose compressed air systems with enough power for the work you want to perform. A quality air compressor helps in cleaning a wide range of mechanical parts. It’s often hard to clean behind the fissures inside rotors while you’re performing brake replacement jobs. But with the help of compressed air systems, you can complete vehicle cleaning jobs quickly and easily. - Pneumatic tools: Air ratchets, airbrushes, sandblasters for sand blasting, paint sprayers for the painting process, air saws, and air sanders are examples of essential tools your mechanics may use. This equipment is powered by, you guessed it, air compressors.

- Tire inflation: Without air compressors, tire inflating facilities and garages are unable to operate. They are a piece of crucial equipment for shops that regularly inflate tires. In these situations, choosing the appropriate air compressor or digital tire inflator can increase your output.

Tips for air compressor maintenance

The tools, no matter how great they may be, mean nothing if they’re not well looked after and maintained. Air compressors are no different.

The following components are the most important to inspect, clean, and lubricate tools on time:

- Belts

- Motor bearings

- Intake vents

- Air filter

- Oil filter

- Lubricant

- Air dryer

- Amps

- Oil level

- Temperatures

- Vibration

- Voltage

Closing thoughts

You can make auto repair services in your shop more manageable with the right equipment & tools. And a quality air compressor will help your techs feel comfortable while spending long hours under the hood.

The right air compressor means better shop productivity and happier staff. But its true value comes from how efficiently it’s used day to day. The right technology, like a mechanic shop software, helps coordinate repair jobs and prevent bottlenecks at workstations, so your shop doesn’t get chaotic quickly. That means your air compressor—and every other tool in your shop—consistently works at peak performance.

We hope our list helps you find the perfect air compressor for your needs!

FAQs

What size air compressor do I need for an auto shop?

For an auto shop, the size of the air compressor you need will largely depend on the specific pneumatic tools and the frequency of their use. Most auto repair tasks require an air compressor that delivers about 4 SCFM at 90 PSI for tools like impact wrenches or ratchets. However, for a general auto shop setup, air compressors ranging from five to 30 horsepower with 80 to 240-gallon air receivers are typically sufficient to handle most tasks efficiently.

Who sells the best air compressor for an automotive shop?

The best air compressor for an automotive shop can vary based on your specific needs such as power, size, and usage frequency. However, the choice of where to buy should consider factors such as after-sales service, warranty, and whether they offer compressors that meet the specific horsepower and capacity requirements of your auto repair shop. Consulting with a specialized provider like Compressed Air Advisors Inc. can also help in making an informed decision, as they often have a range of compressors ideally suited for automotive work.