Whether it’s a slow season or one of the busiest times of the year, there’s no time to pause and get complacent! Your technicians will spend the same number of hours at the shop regardless.

Technicians are the center of every auto repair shop, and as a shop owner, it’s your duty to ensure they’re utilizing their abilities in the right areas.

If your techs are working around the clock, but your shop isn’t making enough profit, then clearly there is an issue. There is a lot you can do to understand what the problem is. But let’s start by understanding the difference between your technicians’ productivity and efficiency. As a shop owner, you should know what both of these mean so you can take clear steps to maximize them.

The difference between technician productivity vs efficiency

Let’s start by differentiating the two terms: productivity and efficiency. Take a moment to answer these:

- Is your shop productive?

- Does that mean it is efficient?

- Do profits mean productivity?

The truth is, there is no clear way to equate it. Both productivity and efficiency have different meanings.

Defining technician productivity

Technician productivity is the percentage of a technician’s clocked-in time spent working on vehicles. It means the output or the volume produced by the technician, that is, the number of jobs they complete in a day or an hour. For example, the technician might be busy all day, but if they only complete one job and bill it to 8 hours, then they are not productive. On the contrary, if a tech is completing three or more jobs in a day, that means they are more productive. It is a clear indicator of how the shop keeps the technician busy with billable hours.

Defining technician efficiency

Technician efficiency means the speed at which a technician can work. Here, you compare the number of hours your tech is working and the number of hours you bill your customers. This means that if your technician is super-efficient, they finish enough tasks so you are able to bill at least 10-11 hours.

Very simply, it is the ratio of billed hours for a job to the actual hours it took to complete it. It indicates your technician’s skill and speed.

Why are both technician efficiency and productivity important

Both efficiency and productivity are important to measure because they affect your billable hours. Plus, if a technician is highly efficient, i.e., fast and skilled, but has low productivity, that probably means the shop doesn’t have enough work for them. Measuring and keeping track of both gives you a good understanding of each technician’s performance and the shop’s workflow.

Why are both technician efficiency and productivity important?

Both efficiency and productivity are important to measure because they affect your billable hours. Plus, if a technician is highly efficient, i.e., fast and skilled, but has low productivity, that probably means the shop doesn’t have enough work for them. Measuring and keeping track of both gives you a good understanding of each technician’s performance and the shop’s workflow.

How to calculate technician productivity and efficiency

So, now you have a clear understanding of what technician productivity and efficiency mean and how they are different. Let’s get down to how they are both calculated.

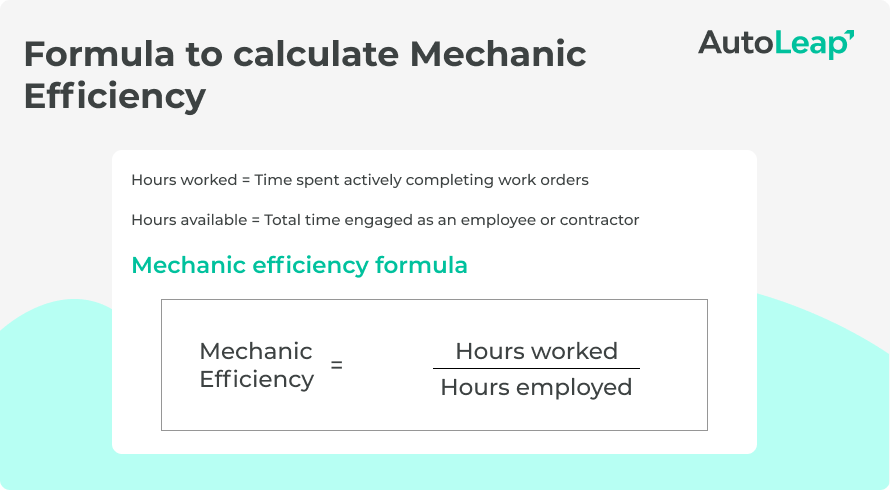

Technician efficiency formula

Efficiency % = (Total billed hours/ Actual hours spent) × 100

So, for example, a job is billed for three hours, but your technician finishes it in two hours. Then that means (3/2) × 100 = 150%. Or the same job takes four hours when done by another technician, then the efficiency % will be (3/4) × 100 = 75%.

But a technician clocked in for eight hours doesn’t spend every single second of that shift working. It is simply not possible. So this is where technician productivity comes in.

Technician productivity formula

Productivity % = (Total hours billed/Total hours clocked-in) × 100

Let’s break it down. For example, if a technician is working on cars for 6 hours out of their 8-hour shift. Then, according to the formula, it will be (6/8) × 100 = 75%. This means their productivity percentage is 75%.

Conversely, if you have a super-efficient technician who is able to do 3 jobs in a six-hour day. You bill three hours on the first job, two and a half hours on the second job, three and a half hours on the third job, then, according to the formula, the productivity percentage will be (9/6) × 100 = 150%.

However, this formula can only provide you a surface level figure of efficiency in your shop. Use of further metrics can help you build your team and understand the actual capacity your auto repair shop has the potential for! Some more metrics to keep in mind include:

- Utilization rate: This formula uses the total number of billable hours worked by an employee, dividing by their total hours available. This expresses how much of their time goes directly into revenue generating work.

- Mean time to complete (MTTC): MTTC calculates the average amount of time that elapses between an issue occurring to the task being completed (includes scheduling, repair and billing time). This will help in identifying any bottlenecks that may be slowing down your technicians’ efficiency when completing tasks.

- Average labor rate: This calculates every cost associated with an employee and divides it by the number of hours worked by the employee. This is especially important when considering the business outputs of hiring more qualified technicians who may expect higher pay.

- Jobs completed per technician: This jobs completed metric is essential for shop owners. It helps you to stay aware of who your most qualified technicians are and each mechanic’s contribution to the overall efficiency of the company.

- Shop capacity: Sometimes it isn’t your technician who isn’t productive. Instead, it’s the production capacity of your shop that’s limited! To understand this dilemma, shop capacity measures the maximum output that can be achieved by your current level of equipment.

Once you’ve calculated some basic statistics to understand where your shop currently stands, it’s important you don’t get lost in the rabbit hole of numbers and calculations. Accurate data is essential when calculating efficiency, and reporting feature of AutoLeap ensures that completed jobs are documented with precision, helping shop owners measure and optimize their mechanics’ performance.

Challenges that reduce technician productivity

Your technicians might be facing a few challenges that reduce their overall productivity. Some things are beyond your control, but a few you can look into. These include:

Downtime between jobs

Sometimes your technician has to wait for the next repair order to come, and there is nothing they can do in that downtime.

Parts delays

Your technicians might spend time searching for parts or waiting for deliveries. For this, you can organize your parts inventory clearly so there is less time spent finding them. Plus, to reduce wait times, you can order in advance or keep a stock of commonly sold parts on hand.

Inefficient workflows

Your bays might be cluttered or poorly organized. Instructions might be unclear. These can be countered by a little cleaning and organizing after each job.

Lack of training

Your technicians might be struggling with new vehicles or technologies. Make sure to keep them updated with the latest technologies so they don’t face any issues when working with new vehicles.

Communication gaps

A lot of time is lost waiting for customer approvals or clarifications from the service advisor. These gaps can further increase the time it takes for the technician to finish the assigned job.

How to increase technician productivity

You can help your technicians by creating an environment that helps improve their productivity and makes the shop more efficient. A few steps you can take:

Train your technicians

Invest in their continuous education and training. Help them take any courses or workshops that can keep their skills sharp, and help them learn about new technologies like EVs and ADAS.

Make your workflow clutter-free

Organize the tools, keep the bay area clear and free of hindrances, and make sure parts are available so they don’t have to waste time waiting for them.

Work on communication

A transparent and smooth flow of communication is also very important. Whether that is internal or with customers. Look into modern shop management tools like AutoLeap to track technician progress, productivity, and plan your week in advance to reduce communication delays and keep everyone well-informed.

Establish goals

Right from the beginning, set realistic productivity and efficiency targets for the team. Know exactly how much time goes into which task, and assign work accordingly.

Automate processes wherever possible

Invest in auto repair shop management software to automate invoicing, appointment scheduling, parts ordering, and reporting to take the load off technicians and reduce hiccups in the workflow. Not only does this free up time for technicians from administrative tasks, but also reduces human errors often caused by manual data entry and recordkeeping.

Closing Thoughts

The truth is, productivity will fluctuate from day to day and week to week. But what matters is that the overall productivity and efficiency trends are upwards, and they are leading the shop towards increasing year-on-year profits. Keeping a close eye on productivity levels can help you make adjustments to processes and improve your bottom line.