As a shop owner in the automotive industry, you know how opening a new shop or upgrading an existing one is a taxing task. You need to have the right tools to service your clients. If a client comes in with certain requirements and you don’t have the right tools on hand, it gives a bad impression and shows that your team isn’t skilled enough. You don’t want to turn away customers or experience any delays. You’ll lose revenue.

So here’s a complete checklist on which mechanic shop equipment you need in your shop to avoid such problems. We cover everything from heavy machinery to smaller tools, to help you decide where to invest your money.

The ultimate auto repair shop equipment list

Let’s break down every category of equipment and help you understand the function of each of these.

Equipment for heavy lifting & support

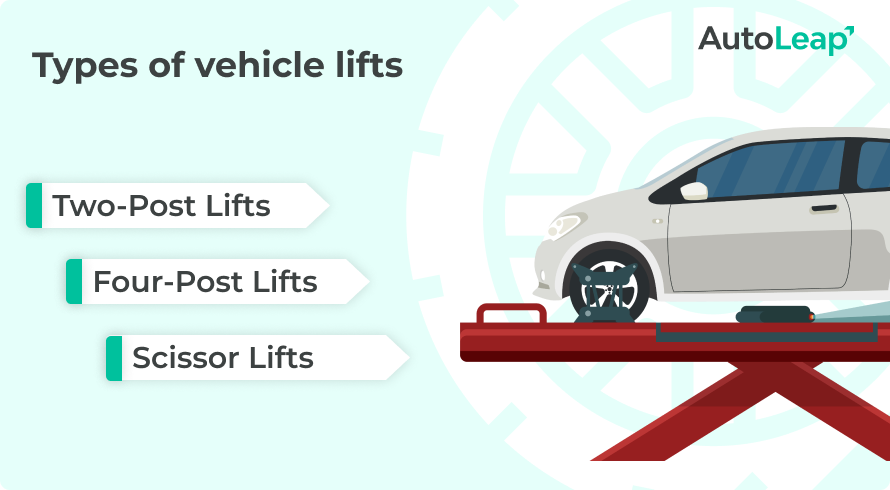

Vehicle lifts

These heavy lifts are needed to safely lift the vehicles off the ground. This gives mechanics easy access during inspections and repairs. There are three main types of vehicle lifts.

Two-post lifts have two columns on both sides of the vehicle. Both columns have arms that extend to help lift the vehicle from its frame. This gives your mechanic access to wheels, suspension, and other components, helping them change tires, fix brakes, or carry out suspension repairs.

Four-post lifts, in comparison, have four columns instead of two. This has two runways where the vehicle can be driven and parked. This is able to lift the vehicle up with the tires, which gives mechanics extra access to the undercarriage. The good thing about the four-post lift is it can work with many vehicle sizes and weights.

Scissor lifts have a mechanical system of linked arms. These help raise the vehicle. Scissor lifts are compact and can easily fit into a smaller shop with limited space. These can also be very handy for quick repairs, tire services, apart from the usual undercarriage work.

Symmetrical lifts and asymmetrical lifts

Symmetrical lifts have arms at the front and the back of the same length and design. The columns are directly across from each other. Two post lifts were symmetrical lifts initially when they came out. It is perfect for trucks and vehicles with longer wheelbases.

Asymmetrical lifts, on the other hand, have shorter arms than rear arms. The column can turn by 30 degrees, and allows for easier door openings, which allows mechanics to easily enter and exit. The front arms take ⅓ of the vehicle load, and the back arms take ⅔ of the load.

Jack and jack stand

Jack stands are needed for safety in an auto repair shop. These are used for quick lifting jobs. They give stable support when the mechanic is using a vehicle lift to prevent any accidents. It is a great way to add an extra layer of safety for your technicians.

The transmission jack is used to remove and install transmissions. Again, the purpose of this jack is to give a stable platform. It gives mechanics an adjustable height so they can get heavy transmissions in and out of vehicles.

Floor jacks, on the other hand, are heavy, hydraulic lifts that use fluid pressure to smoothly lift the vehicle. These give stable and low clearance access, so they are great for undercarriage work, oil changes, and tire rotations.

Engine hoist

The engine hoist, also known as the cherry picker, is used to remove or install engines during repairs. It comes in many different designs and capacities so it can work with engines of various sizes and weights. Again, this is a great way to ensure extra safety and support, reducing the risk of injury in heavy lifting.

Hydraulic press

A hydraulic press is used to install or remove bearings, bushings, or other press-fit parts. It is also very useful in tasks such as bending, straightening, and even shaping metal components.

Make sure you buy one that works well with the type of jobs you need to perform. Plus, it needs to fit into your shop easily, so check your shop’s layout before buying this press.

Diagnostic and electrical tools

Diagnostic scanners

Diagnostic scanners like the OBD-II scanner are used to read error codes, access live data, and help mechanics with system tests on modern vehicles. There are a few different types of OBD-II scanners:

- Basic code readers are simple, affordable, and very easy to use. These are great for your shop if your mechanics need to check and clear diagnostic trouble codes (DTCs).

- DIY scanners are great for home mechanics. These give access to live data streams, and let’s users check various sensors and system performances. These have more features than the basic code readers, but are still very affordable.

- Professional scanners, however, give mechanics advanced diagnostics. These let them access manufacturer-specific codes, advanced data, and even bidirectional controls. With this, mechanics can reset service lights, calibrate sensors, and also interact with various vehicle systems and components.

For an auto shop, it makes sense to invest in a professional scanner so it can help mechanics service vehicles more efficiently.

Multimeter

The multimeter is a great tool for diagnosing any electrical issues in the car, whether that is shorts or open circuits. It measures voltage, current, and resistance and helps troubleshoot any issues like bad batteries, alternators, fuses, and sensors.

Battery charger and jumper

You will have customers who come in to get their vehicle batteries serviced. For them, you need a battery charger. Choose the battery charger that allows you to automate the charging process with smart charging tech.

Plus, a portable jump starter is also a good-to-have in your shop for jump-starting vehicle batteries. It helps you take care of any battery issues, so you don’t have to rely on other vehicles.

Air compressor & pneumatic tools

The air compressor is a must-have for your repair shop. This gives compressed air for different tools and equipment. There is the piston compressor for general use, and the rotary screw compressor for continuous operations and bigger shops.

It is used in inflating tires and even powering pneumatic tools such as sanders, impact wrenches, ratchets, and blowguns. The pneumatic tools need compressed air from the air compressor. The most common ones, apart from the ones mentioned before, are grinders, shears, jackhammers, and riveting guns that you might have in your shop.

Wheel and tire service equipment

Tire changer and wheel balancer

Offering tire-changing services is one of the easiest ways to rake in revenue. Having a tire changer and wheel balancer can help you create a new revenue stream. Tire changers help simplify the tire installation process by helping mechanics mount new tires on rims and dismount old ones quickly and safely. Otherwise, the tire changing process can be an extremely physically demanding process.

There are many different types of tire changers

- Swing-arm tire changers are easy to use, affordable, and have an adjustable tabletop with four tabletop jaws.

- Tilt-back tire changers are best for new mechanics as they are fast and more intuitive equipment.

- Leverless tire changers are more suited for heavy tires. These are also premium quality and are risk-free.

- Heavy-duty tire changers are expensive and best suited to service tires of fleets and other commercial vehicles.

The type of tire changer you go for depends on the types of vehicles you service. Is your shop catering to fleets or commercial vehicles? In that case, you can get heavy-duty tire changers.

The wheel balancer is used to check the weight distribution in the wheel to stop any vibrations. The wheel balancing machine spins the wheel at a high speed, just like it moves on the road. Then the mechanic can check for vibrations in the steering wheel, floorboard, or seat, or they can also look for uneven tire wear.

Wheel alignment machine

Again, a wheel alignment machine is an investment, as it is a high-demand service and can help you increase revenue. Wheel alignment means the angles of the vehicle’s wheels are adjusted to match the manufacturer’s specifications. Aligning wheels helps the vehicle drive straight, which also means tires wear evenly.

Fluid management

There are different tools and equipment to have in your auto shop for fluid management. These include

- Oil drain and caddy is used when changing oil in vehicles. It can drain and transport used oil safely to disposal or recycling areas.

- A fluid evacuator is used to remove fluids such as transmission fluid or coolant. Using this means you don’t need access to a drain plug or need to lift the vehicle.

An A/C recovery & recharge machine is needed for legally and efficiently servicing vehicle air conditioning systems. These help regass car A/C systems and can recharge, recover, and recycle car refrigerants.

Speciality service equipment

There are a few speciality service equipment that you can buy for your shop. These help you perform custom and luxury model repairs more efficiently.

Brake lathe

A brake lathe, as the name suggests, is used to repair car brakes. It helps a vehicle’s brakes with improved performance and also increases the life of the brake components. It is cost-effective and helps mechanics save plenty of time. Plus it also enhances braking efficiency and reduces noise. With all this, your shop can increase profitability on brake jobs.

Strut compressor

A strut in a vehicle is part of the suspension system. It combines a shock absorber and coil spring that helps reduce vehicle vibration. A strut compressor, very simply, is used to compress these strut springs. These help your mechanics remove the coil spring. But these need a locking mechanism as well to ensure safety for your mechanics.

Welder

A welding machine is used to join together vehicle parts like frames, panels, and exhaust systems. For example, it can connect pipes, mufflers, and catalytic converters. MIG welding is a common welding technique used for general fabrication and repairs.

Foundational hand tools

There are a number of hand tools used in an auto shop as well. These are the basis of any toolbox, and are needed for every job. Hand tools help mechanics perform tasks with accuracy and precision. These include:

1. Ratchets and sockets

Ratchet Set: Includes ratchets of different sizes for efficient tightening and loosening of nuts and bolts.

Socket Set: Provides a range of socket sizes to fit different bolt heads, from standard to deep sockets for accessing recessed bolts.

2. Wrenches

Combination Wrench Set: Includes wrenches of various sizes. This allows you to handle different nuts and bolts with ease.

Adjustable Wrench: Useful for tasks where a specific size wrench is not available. As it can be adjusted to fit different bolt sizes.

3. Pliers

Needle-nose Pliers: Ideal for gripping and maneuvering small objects or reaching into tight spaces.

Slip-Joint Pliers: Versatile for gripping and turning objects of various sizes with adjustable jaw positions.

4. Screwdrivers

Phillips and Flathead Screwdrivers: Essential for driving and removing screws of different types and sizes.

Precision Screwdrivers: Handy for delicate tasks requiring small and precise screw handling.

5. Hex keys

Hex keys are also known as Allen keys. Important for tightening and loosening hexagonal bolts and screws. These are commonly found in automotive applications.

6. Specialty bits

Include specialty bits such as star (Torx) and Phillips bits for working with different types of screws and fasteners.

Toolbox/Storage is needed to neatly organize and protect the tools. The toolbox needs to be durable, and if it’s a rolling toolbox, that is an added advantage. Your mechanic won’t have to carry it around the shop.

Torque wrenches are used to tighten nuts and bolts. It is a precision tool that helps mechanics tighten difficult and hard-to-reach parts according to the manufacturer’s exact specifications. Otherwise, overtightening and undertightening can affect vehicle’s performance.

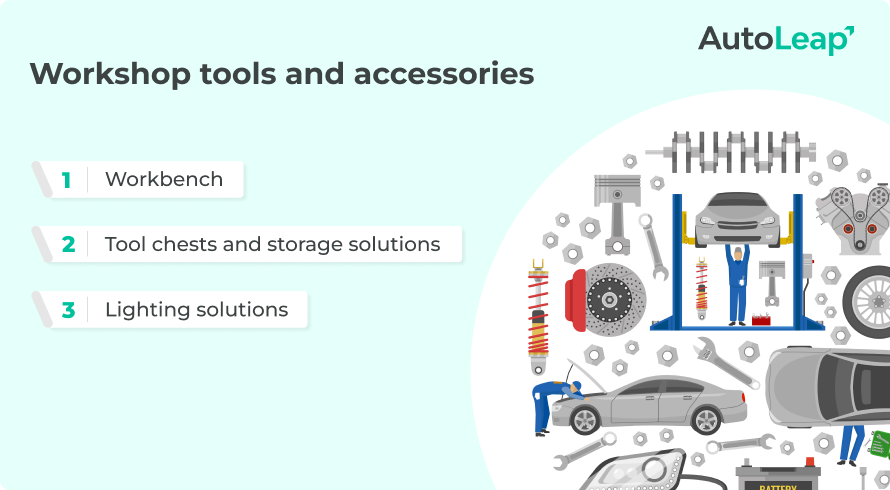

Shop operations and safety

There are other equipment that are a great addition to your auto shop. These help smooth out shop operations and enhance safety. For example

- A workbench with vise is a heavy-duty surface or a workstation for mechanics. It is basically a bench with a mechanical clamp attached to it. It can hold objects as the mechanic is cutting, assembling, disassembling, and working on various components.

- Personal protective equipment is also necessary, and it includes

- Safety glasses to protect from shards and debris

- Gloves to protect from harmful liquids and substances

- Steel-toed boots to protect feet in case of any falling objects

- Hearing protection as there are lots of loud noises in the shop.

Shop management software that can take on a lot of the mundane, repetitive tasks. Plus, it helps improve productivity, and can handle everything from digital vehicle inspections, estimates, invoices, and even customer communication. With all this sorted with an all-in-one solution, you have more time to focus on repairs, maintenance, and servicing customers.

What to consider when choosing mechanic shop equipment

So now you know the many different types of equipment there are. From heavy machinery, right down to the smaller hand tools, to the shop management software. There are alot of decisions to be made, and ofcourse all of this requires a heavy investment. Here are a few questions for you to answer before you buy any of the above equipment for your mechanic shop.

What services is your auto shop offering?

You need to pre-define what services your shop is going to offer, so you can get the necessary equipment accordingly. For example, if your shop does not service vehicle air conditioning systems, you don’t have to invest in an A/C recovery machine for that service. Or if your shop doesn’t offer tire-changing services, then you can leave out the tire changer equipment.

What is your shop's size and layout?

The space you have in your shop will determine the size and type of equipment you can keep. For example, a vehicle lift is not only heavy to install, but also takes up a lot of space. So you need to consider if your shop has the space to keep a four-post lift, or if you will have to go for the more compact scissor lift?

Again, that also depends on the type of vehicles you service. Does your shop mostly have SUVs, trucks, fleets, or sports cars? All of this helps you decide which equipment to go for.

What is your budget and expected ROI?

Of course, you can’t begin on investing any equipment without defining your initial budget. This is a huge upfront cost to undertake, so make sure you are financially ready to make that investment.

Balance this cost with the long-term value and ROI you expect from this. Plus, it is always a good idea to consider any financing options for any of these major purchases.

Will you get new or used equipment?

Getting used equipment is always an option if purchasing new equipment is over your budget. But you must thoroughly inspect the equipment and make sure it is not worn out and still in good condition. You can map out the pros and cons of each, and even mix and match the equipment. Get a few used ones, and invest in a some new equipment.

All depends on your needs, budget, and the type of vehicles you service.

Is the brand reliable?

Do your research on the top-rated and most reliable brands in the market before you make any purchases. Look for real customer reviews, check Reddit threads, and ask peers in your professional circle for their opinion.

See what they are saying. Also, check for customer support. You need brands that offer good customer support so whenever you face an issue, you will know where to go for help.

How to maintain the equipment and keep it safe

Now that you’ve made such a heavy investment in your equipment, you need to also have processes in place that help you keep it safe. These tools last for years, only if you properly maintain them. For example, all the hand tools need to be cleaned after every use to make sure no fluid, oils, and other chemicals remain. That will make it rust faster. So here’s what you can do:

- Carry out regular inspections. Create a checklist for daily, weekly, and monthly checks on all equipment. Some will be checked weekly, and others can be inspected monthly based on their requirements. This also helps keep the equipment safe to use for your staff.

- Calibrate tools as mentioned regularly. Tools like torque wrenches, and wheel alignment systems need to be calibrated. Check the manufacturer specifications, and calibrate them as mentioned.

- Enforce safety protocols. All your staff need to be trained on proper and safe equipment operations. Especially heavy equipment like vehicle lifts. Before any member of staff can operate, they need to undergo training. Plus, your auto shop also needs to follow OSHA guidelines for safety.

Wrapping up

Having the right equipment in your auto shop can help increase efficiency and ensure the safety of your shop. You won’t have to turn away customers just because you don’t have the necessary equipment.

Plus, having the right equipment also means your mechanics can do quality work, save time, and be more productive. Use this extensive guide to make informed decisions when you are upgrading your shop equipment.

FAQs

What equipment is needed to start a mechanic shop?

When starting a mechanic shop, get one vehicle lift, a professional OBD-II scanner, basic hand tool sets, an oil caddy, and jack stands.

What are the most important auto shop tools and equipment?

The most important auto shop tools include a reliable vehicle list, a good diagnostic scanner, a good quality hand tool sets. This will be a good combination to get your shop started.

How much does essential mechanic shop equipment cost?

Essential mechanic shop equipment for a basic one-bay setup can start around $20,000. While a fully-equipped, multi-bay shop’s equipment can go up to $150,000.

Should I buy new or used auto repair shop equipment?

You can get a few new items, such as diagnostic scanners and alignment machines. But equipment like lifts, press or even a toolbox can be used, and that can help you save money. But make sure the used equipment is also in good condition.